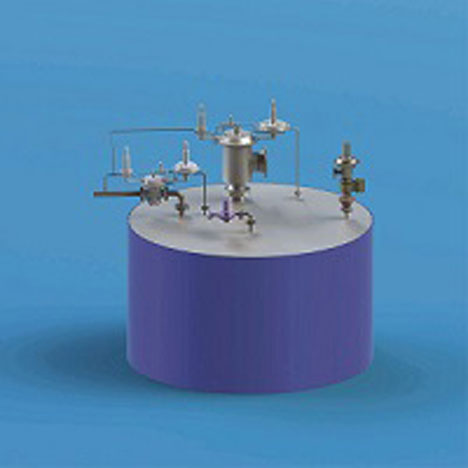

Tank Blanketing Solutions

In refineries & chemicals plants explosive hazards occur if air enters tanks containing volatile flammable liquid during pumping operation. When liquid is removed from a tank or an ambient temperature reduces, vacuum may develop. Hence, for optimum protection of tank, contents and the environment, a low positive constant gas pressure is maintained in the vapor space of a storage tank. A blanketing gas, nitrogen being the most popular, serves to reduce the oxygen content in the vapor space, making it inert and eliminate the possibility of combustion. It also prevents the ingress of air and moisture from entering the storage vessel. When liquid is removed from tank or an ambient temperature reduces, vacuum may develop. Blanketing system prevents any vacuum from development and maintain the desired blanket pressure. In addition to this, a blanketing gas pressure reduces the evaporation of the stored product to a negligible amount. The result not only conserves product but also greatly reduces emissions. Quality of chemicals which gets affected by contact of moisture or oxygen, is protected by blanketing. These advantages are in addition to the fire protection that is provided.

Flame Arrestor

The accidental ignition of flammable gases or vapours from vent pipes of storage tank or process vessel presents a constant threat to plant and personnel. The use of the flame arrestors is one of the essential measures taken to avoid or minimize the possible consequences. Their application is widespread, ranging from the protection of small solvent tanks to the safety of large and complex process plant. The oil, gas, petroleum, chemical and petrochemical industries are major users. A flame arrester is a static device which stops a flame entering into the storage tank or process vessel containing a flammable gas or vapour. An end -of-line type flame arrestor is fitted at the extreme downstream end of a pipeline. The arrester consists of a flame quenching element contained within a housing which incorporates thread or flange connections for fitting to pipework. The element is often of greater diameter than the pipework in order to compensate for pressure drop and therefore the housing is enlarged accordingly.

Breather Valve

BV-100 & BV-101 series valves are highly developed pressure and vacuum relief valves with excellent flow performance. These valves are useful as relief valves for blanketed vessels in which solvents are filled & drawn at a high flow rate. This valve is installed in the in-and out breathing lines of tanks, vessels and process equipments to protect against unpredicted fluctuations in pressure & vacuum. By retaining toxic vapors and avoiding atmospheric contamination, these valves provide increased fire protection and safety. Pressure cum vacuum relief breather valves are designed to protect tanks from possible casualty due to over pressure created by thermal expansion and product movement into the tank and excessive vacuum created by thermal contraction and product movement out of the tank. At the same time it minimizes costly product evaporation / loss. Continued design improvements of these valves provide high efficiency, maximum flow capacity and minimum leakage. The product vapors can be discharged through a collective line connected to the line flange on the pressure side (Model: BV101). If the vapors are flammable, connect a detonation flame arrester.