Fiber Laser Cutting Leads to Business Diversification. The Fiber Laser Metal Cutting technology has filled a production hole in metal forming industries, delivering flexibility as well as time and cost savings. Adopting Fiber Laser Metal Cutting Machine is a boon for service industries manufacturing space under one roof, serve a variety of markets, including appliance, automotive, furniture, medical, electrical and industrial-hardware. It performs tool build, stamping, fabricating, assembly and painting in-house, using a variety of part materials. Its specialties breaking in to the production schedules of outside suppliers, and quality control of the parts. User friendly benefits of Fiber Laser Metal Cutting Machine from offsite and in-house training backed by the machine's library of material-cutting conditions and job-recall capability, quickly realized the advantages of fiber-laser cutting.

Fiber Laser Cutting increases Industry ability to help customers develop parts in a quicker manner, Manufacturer can make multiple iterations of a fabricated part very quickly to validate a concept with customers, so it helps us in the early suppler-involvement process of part development." In Metal Forming Industry requirements are from Low-Volume to High Volume in Million Parts Which are easily manufactured in Fiber Laser Cutting Machine.

It is a big solution for an Industry fabricating a stainless-steel panel which requires a size variation Now laser cutter able to create a whole family of those different-sized products/parts just by changing blank development to a laser-cutting process instead of a die-cutting process. With the In-House laser cutter. To outsource this type of work would have been costly, with lead time becoming a significant issue.

Laser-cutting machine has a lead time advantage, and better customer service. For example, during product development, you can meet with customers and produce a prototype to use as you share your ideas. The ability to produce parts quickly is a huge advantage.

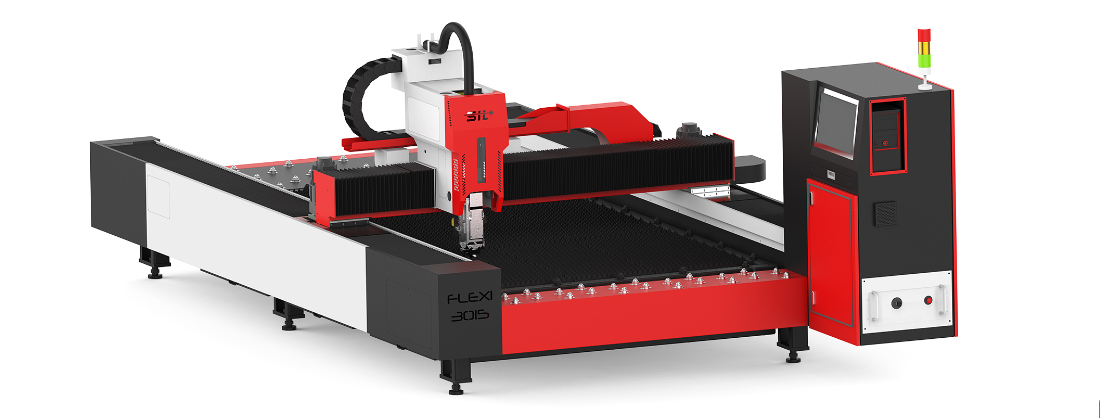

| Laser Source | 700 / 1000 / 1500 W IPG Or Raycus |

| X axis Stroke | 1525 mm |

| Y Axis Stroke | 3050 mm |

| Z Axis Stroke | 230 mm |

| Working Area | 1500 mm X 3000 mm |

| X – Y Positioning Accuracy" | ±0.05 mm/m |

| Maximum Acceleration | 1.5G |

| Rapid Speed | 120 M/min |

| Controller | Cypcut FS 2000 (BCS 100) |

| Servo Motors & Drives | Yasakawa Sigma 7 / Panasonic |

| Rack & Pinion | Atlanta Germany Q6 Grade |

| LM Guide | Hi Win (Taiwan) ORIGINAL |

| Cutting Head | Raytool Autofocus BM 109 Motorized (Swiss) |

| Gear Box | Precision Low Backlash (German) |

| Water Chiller | Tongfie (China) |

| Dual Pallet Changer | Optional |

| Enclosure Body | Optional |

| Pneumatics | SMC (Japan) |

| Gas Pressure Control System | SMC / ASCO(Japan) |

| Gas Pressure Limit Switch | Danfoss (Germany) |