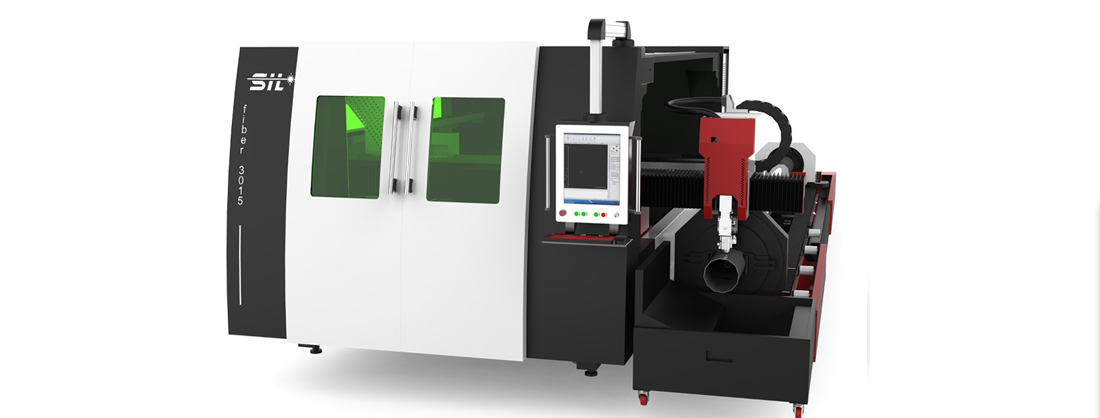

Metal Sheet – Pipe Fiber Laser Cutting Machine is an example of high-tech flexibility 3D axis cutting. The system blends beam-modulation technology to automatically match material thickness with the power and speed of a rotary index to efficiently transition from flat sheet to tube or pipe cutting. This switch between flat-sheet cutting and tube or pipe cutting is accomplished in less than 2 min., and the system's ability to process round, square, rectangle, C-channel and angle iron provides users with extreme versatility.

The beam-modulation technology allows for a continuous variable beam across every thickness of material without having to change lenses, while ensuring fast throughput. As the material thickness increases, so, too, does the diameter of the laser beam and the width of the cut, enabling easy removal of finished parts. The Combo system Metal Sheet – Pipe Fiber Laser Cutting Machine is widely used in kitchen appliance, electrical panel box, mechanical systems, electrical manufacturing, elevator manufacturing, and auto parts, hardware, Structural Steel Plants etc.

Material Such as Stainless Steel, Mild Steel, Galvanized, Zinc – Coated Steel, Aluminium, Brass Sheet & Pipes are processed in Combo system. SIL combo model comes with specification of fiber laser 1000w to 4000w power, includes 160 & 220 diameter maximum pipe cutting. 300mm Z-axis range with 1500x3000 mm sheet size.

| Laser Power | KW | 1-4 |

| Laser Model | IPG/Raycus | |

| Work Size | mm | 3000×1500 |

| Positioning Accuracy | mm/m | ≤±0.05 |

| Rotary Size (Combo) | mm | 165/220 Ø |

| Max Idle Speed | m/mm | 60 |

| Repositioning Accuracy | mm | ≤±0.03 |

| Power | V/Hz | 380/50 |

| Cutting Acceleration | G | 0.5 |

| Weight | Kg | 8000 |

| Controller | Cypcut | |

| X Axis | mm | 1520 |

| Y Axis | mm | 3050 |

| Z Axis | mm | 300 |