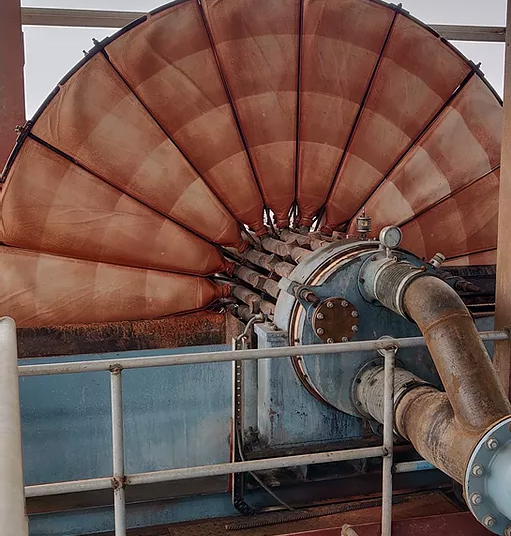

Indofab Disc Filters are uniquely designed custom built as per the application keeping in mind the Abrasion & wear resistance required for Coarse & abrasive slurries. INDOFAB Disc Filter are modular in Construction and each of the MOC is carefully chosen to withstand the operating conditions. Vacuum Disc Filters are widel used in Minerals & Metal Beneficiation Industry; A VAT/Trough filled usually adjustable 30%-50% of the Disc Submergence takes the feed slurry through Energy dessipating Inlet while the feed volume is large for Disc Filters The Rotary Discs are closely spaced at a pitch of 400-600mm increasing the Filtration rate / area considerably for the smallest possible Foot Print. A central Shaft with very streamline designed flow pattern transfers the filtrate liquor from sectors to the straight inline valve this ensure high rate filtration & drainage. During Rotation adjustable Bridge Plate provides flexibility of adjusting Pickup zone, draining zone, washing, drying zone & Discharge zone, this feature makes it easy for application based adjustments/ fine tuning at site. The Filtrate travels through Receiver to Filtrate Tank at lower levels, while a moisture trap placed on higher elevation levels ensures no filtrate traces report to the vacuum pump. The Accumulated Cake on the Surface of each Sector is discharged near the scrapper with air blow or snap blow action ensuring maximum cake discharge of cake to the Discharge chute. Each Sector is provided with Suitable Filter Media Mesh or Filter Cloth based on the Test work or Mesh size Slurry to be Filtered; These filter bags provide a very handy and economical solution as a set of sectors with filter bags can always be kept ready for easy replacement reducing considerable down time. Modular sectors 12 deg., 15deg, 20 deg, 25 deg and 30 deg. designs are used as per the product & client requirements. Sectors are either interlocked to each other or firmly secured to the Rotary Center shaft thourgh Long Radial bolts. INDOFAB Rotary Vacuum Disc Filters are often used with Coarse Filtration requirements with high filtration rate slurries.

Features

Rotary Vacuum Drum/Disc Filter more popularly known as Vacuum Filters or RVDF; The process is continous filtration of Slurries to separate solids & Liquids through a filter medium by Vacuum. Filter Medium is usually a mesh of Steel or Cloth or PP Mesh or Rare Earth deposition based on the type of Application. Vacuum Filtration can is manily achieved by three methods Rotary Vacuum Drum Filters, Rotary Vacuum Disc Filters and Rotary Vacuum Pan Filters. Selection of Type of Filter & its Filtration media is by proven similar experience or Test Work only. The process usually involves slurry adhering to the rotating surface when under vacuum, as the cycle progresses the cake remains on the surface while the Filtrate/liquid runs downstreams; later in the cycle the vacuum is cut-off to release the cake in discharge zone. The cycle continous in repeated manner ranging from 0.25 RPM to 8 RPM depending on Type and application of Vacuum filters.

Specification

- Mainly the Disc Filter Types are based on 12,15,18, 20 and 30 degree sectors. x No. of Discs.

- 1 Disc Filter to 6 Disc Filter are available with one side Discharge Valve.

- 7 Disc Filter to 12 Disc Filter are available with both Side Discharge Valves.

- Cast Iron Center Shaft Design, Special Ductile Iron Shaft Design and Alloy Steel Pipe Construction Shaft Design Models are available. Selected based on the Abrasive/Wear nature of the slurry.

- Special Perforated Sheet Design Sectors, High Drainage Wire Design Sectors and Heavy Rim design sectors are available for all combination of disc filters. All sectors are very light in weight & easy for Assembly which considerably reduces the downtime.

- Material of Construction can vary for specific application from Graded Cast Iron,Graded Cast Steel, Stainless Steel Various grades like SS316/L SS317L SS304/L are available.

- Disc Filters are usually Start from 1.5 Mtr Dia., 2.0 Mtr Dia., 2.5 Mtr Dia., 3.2 Mtr Dia., 4 Mtr Dia. and 6 Mtr Dia. As per Filtration area requirement.

Application

- Benefication Plants

- Pulp & Paper Industry

- Effluent Treatment Plant ETP

- Wastewater treatment plant WWTP