Pneumatic Press

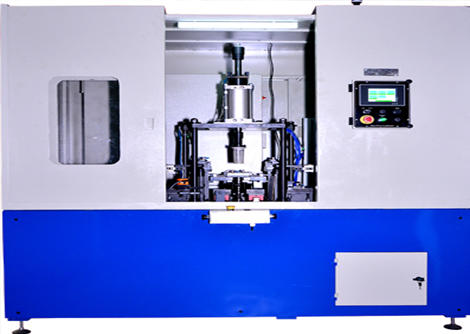

Seal Pressing & Sizing SPM

- Two Station Linear Indexing Machines

- After Loading the Job first Presence of Grooves are Confirmed by Vision Sensor

- Then Two Seal are Pressed Automatically

- After Pressing the Seals again Confirmation is done by Vision Sensor

- Then Job Moves Bak Wards where in Sizing of Seal is done

Glove Latch Assembly

- Manual loading of job and allied child parts

- Cycle start with two hand push button

- Purely pneumatically operated

Assembly SPM of AC Control Panels

- Manual loading of job and all child parts at loading station

- Manually sliding fixture slide to pressing station

- Manually pressing of parts, by two hand push button

- Purely pneumatically operated

Pin Pressing SPM

- Manual Loading of job and pin

- Cycle start by two hand push button

- Depth setting by dead stopper arrangement

- Purely pneumatically operated

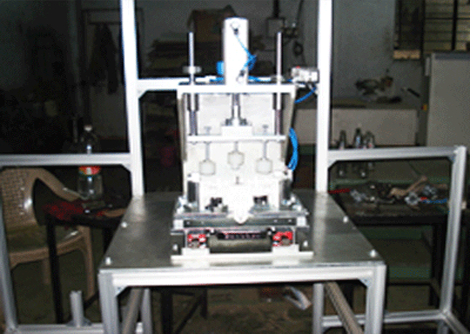

Seal Press

- Manual loading of job into fixture

- Manual loading of seal sleeve and seal on to camshaft

- Cycle start with two hand push button box

- Depth achieved with two stoppers

- Purely pneumatically operated