Cone Screw (Nauta) Mixer

TECHPERT Process Industries has technical expertise in process and mechanical design of Cone Screw Mixers. We have design expertise in Powder + Powder, 3 or more powders in different proportion, Powder + Powder mixing with perfume / protein / Liquid dosing arrangement, Jacketed mixers for heating or cooling arrangement, Pilot Cone Screw Mixers for testing and R&D purpose and Cone Screw Mixers for specific customer applications. Our Cone Screw Mixers are ranging from 100 Lit/Batch to 10000 Lit/Batch capacity. For larger capacity we can supply W type double Cone Screw mixers. Conical screw mixers are used when one of the mixing ingredient's percentage is very low and high mixing efficiency / dispersion is required. The mixing action is very gentle as such generating very low heat. This ensures that product properties are not altered. This mixer requires comparatively low power than the horizontal mixers. It has two motions, one arm is rotating along the periphery of mixer at top and other are that is screw rotating along with it's axis. This ensues very high and equal dispersion ratio and mixing efficiency.

Paddle Mixer

TECHPERT Process Industries has technical expertise in process and mechanical design of Paddle Mixers. We have design expertise in Powder + Liquid, 3 or more powders in different proportion + Liquid dosing arrangement, Jacketed mixers for heating or cooling arrangement, Pilot Paddle Mixers for testing and R&D purpose and Paddle Mixers for specific customer applications. Our Paddle Mixers are ranging from 100 Lit/Batch to 10000 Lit/Batch capacity. Paddle Mixers are used to mix or blend a wide range of materials used in food, pharmaceutical, hemical, mineral industry. The rotating paddles lift and blend two or more mixing material in a quick and intense movement of each particle through the mixing chamber. By defined angle of the paddles, the blender shows an excellent axial and radial dispersion. Optimum sizing of the mixer shell and paddle profile ensures proper mixing efficiency. Spray nozzles can be provided to inject liquids. By roviding jacket or limpet it can be used for blending and drying. Double paddle design is also available where kneading action is required like making doughs.

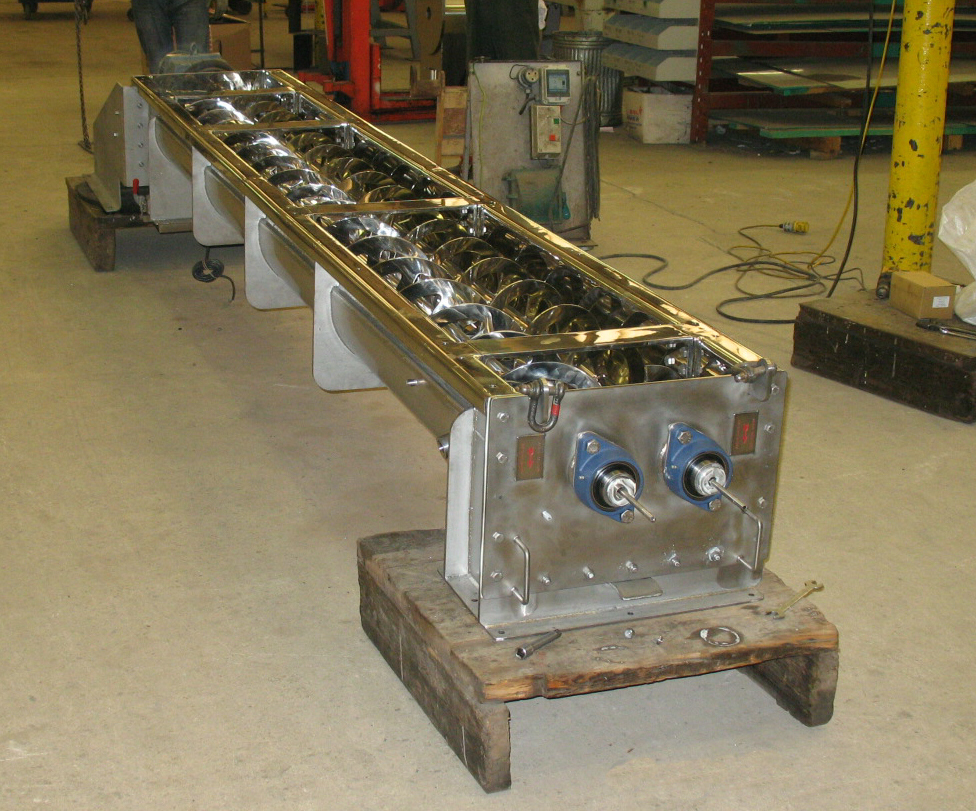

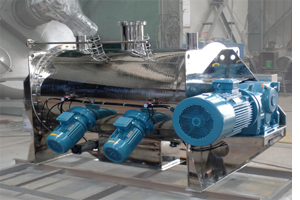

Continuous Mixer

TECHPERT Process Industrieshas technical expertise in process and mechanical design of ContinuousMixers. We have design expertise in Powder + Powder, 2 or more powders in different proportion + Liquid dosing arrangement, Jacketed mixers for heating or cooling arrangement, Pilot ContinuousMixers for testing and R&D purpose and ContinuousMixers for specific customer applications. Our ContinuousMixers are ranging from 500 Kg/Hour to 50000 Kg/Hour capacity. Continuous Mixers are used to mix or blend a wide range of materials used in food, pharmaceutical, chemical, mineral industry. The rotating Paddles liftand blend two or more mixing material in a quick and intense movement, achieving dispersion of each particle through the mixing chamber. By defined angle of the paddles, the blender shows an excellent axial and radial dispersion. Optimum sizing of the mixer shell and Continuous profile ensures proper mixing efficiency. Spray nozzles can be provided to inject liquids. By providing jacket or limpet it can be used for blending and drying. Different blade designs for specific material and application to ensure proper mixing and efficiency.

Plough Shear Mixer

TECHPERT Process Industries has technical expertise in process and mechanical design of Plough Shear Mixers. We have design expertise in Powder + Liquid, High Viscous pastes /Liquids, Jacketed mixers for heating or cooling arrangement, Pilot Plough Shear Mixers for testing and R&D purpose and Plough Shear Mixers for specific customer applications. Our Plough Shear Mixers are ranging from 100 Lit/Batch to 10000 Lit/Batch capacity. Plough Shear Mixers are used to mix or blend a wide range of materials used in food, pharmaceutical, chemical, mineral industry. The rotating Plough blades lift and blend two or more mixing material in the mixing chamber. By defined angle of the Plough Blades, the blender shows an excellent axial and radial dispersion. Optimum sizing of the mixer shell and Plough Shear profile ensures proper mixing efficiency. Also choppers at bottom side of mixing chamber are provided to disintegrate the settling material. This is to avoid lump formation. Choppers act as lump breakers. Spray nozzles can be provided to inject liquids. By providing jacket or limpet it can be used for blending and drying.