Butt Weld Pipe Fitting Reducer Manufacturer, Supplier and Exporter in Mumbai, India

Butt-weld Reducer fitting can be manufactured in various grades of Stainless Steel include 304, 316, 304L, 316L, 317 etc and Alloy Steel include Monel, Inconel, Hastelloy, Duplex Steel, etc. Tube Innovatives (India) is among one of the leading manufacturers and exporters of high-quality pipe fittings by using the latest technology and in-house QC system. We offer our materials with complete certification and as per national and international standards. We also provide Buttweld Pipe Reducers as per your requirement with appropriate quantity order. Refer our Reducer fitting specification and size chart as mentioned below.

| Reducer Specifications | |||

|---|---|---|---|

| Family | Butt Weld Pipe Fitting | Shape | Reducer |

| Material | Stainless Steel, Carbon Steel, Alloy Steel, Duplex Steel, Nickel Alloy | Make | TII |

| Size | 1/8″-48″ | Thickness | SCH 5-SCH 160 |

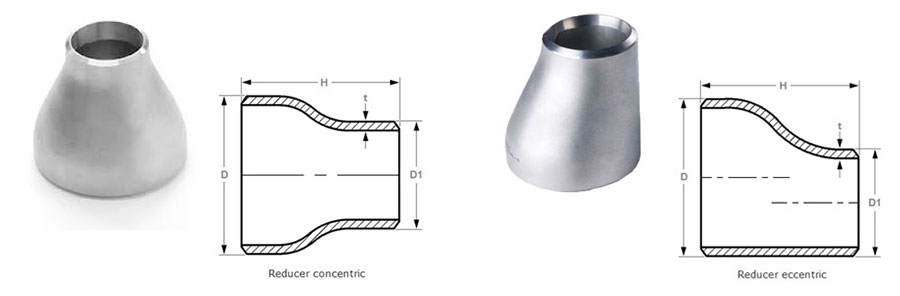

| Type | Seamless, Welded(ERW), Fabricated | Variation | Concentric, Eccentric |

| Finish | Shot Blast, Sand Blast, Electro polish | End | Bevelled |

| Marking | TII-Specs-Description-Heat No. | Packing | Protected by Cap |

| Reducer Size Chart | ||||||||

|---|---|---|---|---|---|---|---|---|

| Code RCD REISO | BIG | SMALL | HEIGHT H mm | THEORETICAL WEIGHT KG | ||||

| DN | D mm | Thickness T mm | DN | D1 mm | Thickness t mm | |||

| 27 21 | 3/4 | 26.9 | 2.3 | 1/2 | 21.3 | 2.0 | 38 | 0.08 |

| 33 21 | 1 | 33.7 | 2.6 | 1/2 | 21.3 | 2.0 | 50 | 0.09 |

| 33 27 | 3/4 | 26.9 | 2.3 | 0.09 | ||||

| 42 21 | 1″1/4 | 42.4 | 2.6 | 1/2 | 21.3 | 2.0 | 50 | 0.12 |

| 42 27 | 3/4 | 26.9 | 2.3 | 0.13 | ||||

| 42 33 | 1 | 33.7 | 2.6 | 0.14 | ||||

| *48 21 | 1″1/2 | 48.3 | 2.6 | 1/2 | 21.3 | 2.0 | 64 | 0.18 |

| 48 27 | 3/4 | 26.9 | 2.3 | 0.19 | ||||

| 48 33 | 1 | 33.7 | 2.6 | 0.20 | ||||

| 48 42 | 1″1/4 | 42.4 | 2.6 | 0.20 | ||||

| 60 27 | 2 | 60.3 | 2.9 | 3/4 | 26.9 | 2.3 | 76 | 0.30 |

| 60 33 | 1 | 33.7 | 2.6 | 0.31 | ||||

| 60 42 | 1″1/4 | 42.4 | 2.6 | 0.32 | ||||

| 60 48 | 1″1/2 | 48.3 | 2.6 | 0.33 | ||||

| 76 33 | 2″1/2 | 76.1 | 2.9 | 1 | 33.7 | 2.6 | 90 | 0.40 |

| 76 42 | 1″1/4 | 42.4 | 2.6 | 0.47 | ||||

| 76 48 | 1″1/2 | 48.3 | 2.6 | 0.48 | ||||

| 76 60 | 2 | 60.3 | 2.6 | 0.49 | ||||

| 89 42 | 3 | 88.9 | 3.2 | 1″1/4 | 42.4 | 2.6 | 90 | 0.55 |

| 89 48 | 1″1/2 | 48.3 | 2.6 | 0.61 | ||||

| 89 60 | 2 | 60.3 | 2.9 | 0.62 | ||||

| 89 76 | 2″1/2 | 76.1 | 2.9 | 0.63 | ||||

| 114 48 | 4 | 114.3 | 3.6 | 1″1/2 | 48.3 | 2.6 | 100 | 0.85 |

| 114 60 | 2 | 60.3 | 2.9 | 0.98 | ||||

| 114 76 | 2″1/2 | 76.1 | 2.9 | 1.00 | ||||

| 114 89 | 3 | 88.9 | 3.2 | 1.02 | ||||

| 139 60 | 5 | 139.7 | 4.0 | 2 | 60.3 | 2.9 | 127 | 1.60 |

| 139 76 | 2″1/2 | 76.1 | 2.9 | 1.70 | ||||

| 139 89 | 3 | 88.9 | 3.2 | 1.74 | ||||

| 139 114 | 4 | 114.3 | 3.6 | 1.76 | ||||

| *168 76 | 6 | 168.3 | 4.5 | 2″1/2 | 76.1 | 2.9 | 140 | 2.60 |

| 168 89 | 3 | 88.9 | 3.2 | 2.70 | ||||

| 168 114 | 4 | 114.3 | 3.6 | 2.82 | ||||

| 168 139 | 5 | 139.7 | 4.0 | 2.94 | ||||

| 219 114 | 8 | 219.1 | 6.3 | 4 | 114.3 | 3.6 | 152 | 5.03 |

| 219 139 | 5 | 139.7 | 4.0 | 5.12 | ||||

| 219 168 | 6 | 168.3 | 4.5 | 5.18 | ||||

| *273 114 | 10 | 273.0 | 6.3 | 4 | 114.3 | 3.6 | 178 | 7.00 |

| *273 139 | 5 | 139.7 | 4.0 | 7.20 | ||||

| 273 168 | 6 | 168.3 | 4.5 | 7.40 | ||||

| 273 219 | 8 | 219.1 | 6.3 | 7.55 | ||||

| 323 168 | 12 | 323.9 | 7.1 | 6 | 168.3 | 4.5 | 203 | 11.00 |

| 323 219 | 8 | 219.1 | 6.3 | 11.10 | ||||

| 323 273 | 10 | 273 | 6.3 | 11.20 | ||||

N.B. code RCD = concentric reducers – code REISO = excentric reducers

* Only concentric

| Tolerance Chart | ||||

|---|---|---|---|---|

| All Fittings | Reducers and Lap. Joint Stub End | |||

| Nominal Pipe Size | Outside (1) Diameter at Bevel | Inside (2) Diameter at End | Wall (2) Thickness | Over all Length F, H |

| 1/2 to 2 1/2 | +1 | +0.8 | Not less than 87.5% of Nominal thickness | +2 |

| 3 to 3 1/2 | +1 | +1.6 | +2 | |

| 4 | +2-1 | +1.6 | +2 | |

| 5 to 6 | +3-1 | +1.6 | +2 | |

| 8 | +2 | +1.6 | +2 | |

| 10 | +4-3 | +3.2 | +2 | |

| 12 to 18 | +4-3 | +3.2 | +3 | |

| 20 to 24 | +6-5 | +4.8 | +3 | |

| 26 to 30 | +7-5 | +4.8 | +3 | |

| 32 to 48 | +7-5 | +4.8 | +3 | |