ELMACO Bench Grinders

ELMACO Pedestal Grinders

ELMACO Pedestal Grinders

ELMACO Bench Grinders

cum Polishers

ELMACO Abrasive Belt Grinders

VIJAY Bench Polishers

VIJAY Flexible Shaft Grinders

VIJAY Coolant Pumps

VIJAY Jewellery Polishers

VIJAY Pedestal Buffer

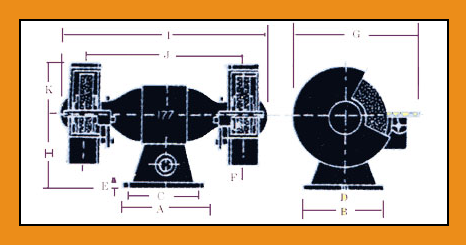

ELMACO Bench Grinders

Bench Grinders are used for grinding of tools, tips, light grinding etc. Each machine is equipped with two Nos. Grinding Wheel

• Used for grinding of Tool, tips, light grindings etc.

• Use of best quality stamping and diecast rotors

• Dynamically Balanced rotor minimizes vibrations and ensures smooth running.

• Construction of the machines are made sturdy and robust to offer vibration free performance.

• Machine provided with Two nos. Grinding Wheel .

• Adjustable tool rests are provided to ensure maximum usage of Grinding wheels . Tool rests are machined to give proper level to the Grinding component.

• Eye Shields are recommended for each machine. The same is supplied as an extra accessory except in 2 H.P. and 3 H.P. machines where they are supplied as a standard accessory.

• Use of high quality grease for lubrication. RECOMMENDED USE OF GREASE LITHON3 OR EQUIVALENT

• All machines are subject to rigid quality control tests.

• Machines of different voltage and different frequency can be supplied against specific orders

• All machines are subject to rigid quality control tests.

• Machines of different voltage and different frequency can be supplied against specific orders

• All machines carry warranty (except Ball Bearings) against any manufacturing defect as per the warranty terms prevailing of the company. No warranty for wear and tear items.

Model |

H.P |

K.W |

Ph. |

R.P.M |

Wheel Size |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

Approx |

BG-41 |

0.25 |

0.18 |

1 |

2800 |

100 |

130 |

130 |

108 |

108 |

13 |

39 |

150 |

115 |

330 |

258 |

65 |

9 |

BG-61 |

0.33 |

0.25 |

1 |

2800 |

150 |

230 |

233 |

204 |

204 |

23 |

55 |

227 |

168 |

472 |

380 |

95 |

32 |

BG-71 |

0.50 |

0.37 |

1 |

2800 |

180 |

230 |

233 |

204 |

204 |

23 |

58 |

248 |

171 |

480 |

385 |

107 |

34 |

BG-81 |

0.75 |

0.55 |

1 |

2800 |

200 |

227 |

232 |

200 |

205 |

27 |

60 |

283 |

202 |

500 |

404 |

120 |

42 |

BG-101 |

1.00 |

0.75 |

1 |

2800 |

250 |

227 |

232 |

200 |

205 |

27 |

66 |

320 |

202 |

516 |

415 |

140 |

57 |

BG-43 |

0.25 |

0.18 |

3 |

2800 |

100 |

130 |

130 |

108 |

108 |

13 |

39 |

150 |

115 |

330 |

258 |

65 |

9 |

BG-63 |

0.33 |

0.25 |

3 |

2800 |

150 |

230 |

233 |

204 |

204 |

23 |

55 |

227 |

168 |

472 |

380 |

95 |

30 |

BG-73 |

0.50 |

0.37 |

3 |

2800 |

180 |

230 |

233 |

204 |

204 |

23 |

58 |

248 |

171 |

480 |

380 |

107 |

32 |

BG-83 |

0.75 |

0.55 |

3 |

2800 |

200 |

227 |

232 |

200 |

205 |

27 |

60 |

283 |

202 |

500 |

404 |

120 |

42 |

BG-103 |

1.00 |

0.75 |

3 |

2800 |

250 |

227 |

232 |

200 |

205 |

27 |

66 |

320 |

202 |

516 |

415 |

140 |

47 |

BG-113 |

1.00 |

0.75 |

3 |

1420 |

250 |

227 |

232 |

200 |

205 |

27 |

66 |

320 |

202 |

516 |

415 |

140 |

48 |

BG-123 |

2.00 |

1.50 |

3 |

1420 |

300 |

255 |

300 |

215 |

255 |

30 |

92 |

405 |

220 |

610 |

460 |

170 |

102 |

BG-143 |

3.00 |

2.25 |

3 |

1420 |

350 |

245 |

264 |

208 |

228 |

40 |

112 |

490 |

250 |

720 |

495 |

220 |

123 |

General Tolerance ± 0.25 % Dimensions, details etc. are subject to change as the quality of machines is improved constantly.