ELMACO Bench Grinders

ELMACO Pedestal Grinders

ELMACO Pedestal Grinders

ELMACO Bench Grinders

cum Polishers

ELMACO Abrasive Belt Grinders

VIJAY Bench Polishers

VIJAY Flexible Shaft Grinders

VIJAY Coolant Pumps

VIJAY Jewellery Polishers

VIJAY Pedestal Buffer

Jewellery Polishers

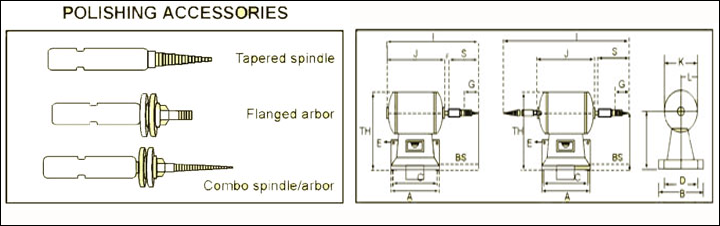

Features :

• C.I. Casting of high grade quality.

• Use of best quality stamping and Die cast rotor.

• Use of SKF or Equivalent Double Sealed Ball Bearings.

• Motor Winding are specially insulated and impregnated with High Grade Insulating Varnish to Withstand Humid and Tropical Climate.

• Dynamically balanced Rotor minimise vibrations and ensure smooth running.

• Each machine provided with Rotory Switch.

• All Bench polishers equiped with reversly threded adoptors to take buffing mops.

• Rotor fans provided to minimise rise in temperature.

• All machines are subject to rigid quality control tests.

• Machines of different voltage and different frequency can be supplied against specific orders.

• All machines carry warranty (except Ball Bearings) against any manufacturing defect as per the warranty terms prevailing of the company. No warranty for wear and tear items.

Jewellery Model - Single Sided

Model |

H.P |

K.W |

R.P.M |

Ph. |

"S" |

A |

B |

C |

D |

E |

F |

G |

H |

TH |

I |

J |

K |

BS |

Approx. Nett WT. in Kg. |

VMT-71 |

0.25 |

0.18 |

3000 |

1 |

110 |

130 |

130 |

108 |

108 |

8 |

- |

45 |

115 |

170 |

353 |

232 |

106 |

170 |

7 |

VMT-73 |

0.33 |

0.25 |

3000 |

1 |

225 |

230 |

233 |

204 |

204 |

10 |

23 |

75 |

170 |

250 |

443 |

195 |

162 |

243 |

21 |

VMT-75 |

0.50 |

0.37 |

3000 |

1 |

225 |

230 |

233 |

204 |

204 |

10 |

23 |

75 |

170 |

250 |

443 |

195 |

162 |

243 |

21 |

VMT-77 |

0.75 |

0.55 |

3000 |

1 |

225 |

227 |

232 |

200 |

205 |

10 |

23 |

75 |

200 |

279 |

466 |

218 |

162 |

230 |

25 |

VMT-79 |

1.00 |

0.75 |

3000 |

1 |

225 |

227 |

232 |

200 |

205 |

10 |

23 |

75 |

200 |

279 |

466 |

218 |

162 |

230 |

26 |

VMT-74 |

0.50 |

0.37 |

3000 |

3 |

225 |

230 |

233 |

204 |

204 |

10 |

23 |

75 |

170 |

250 |

443 |

195 |

162 |

243 |

19 |

VMT-76 |

0.75 |

0.55 |

3000 |

3 |

225 |

227 |

232 |

200 |

205 |

10 |

23 |

75 |

200 |

279 |

466 |

218 |

162 |

230 |

21 |

VMT-78 |

1.00 |

0.75 |

3000 |

3 |

225 |

227 |

232 |

200 |

205 |

10 |

23 |

75 |

200 |

279 |

466 |

218 |

162 |

230 |

22 |

Jewellery Model - Double Sided

Model |

H.P |

K.W |

R.P.M |

Ph. |

"S" |

A |

B |

C |

D |

E |

F |

G |

H |

TH |

I |

J |

K |

BS |

Approx. Nett WT. in Kg. |

VMT- 81 |

0.25 |

0.18 |

3000 |

1 |

110 |

130 |

130 |

108 |

108 |

8 |

- |

45 |

115 |

170 |

474 |

232 |

106 |

170 |

8 |

VMT- 83 |

0.33 |

0.25 |

3000 |

1 |

150 |

230 |

233 |

204 |

204 |

10 |

23 |

68 |

170 |

250 |

596 |

195 |

162 |

168 |

21 |

VMT- 85 |

0.50 |

0.37 |

3000 |

1 |

150 |

230 |

233 |

204 |

204 |

10 |

23 |

68 |

170 |

250 |

596 |

195 |

162 |

168 |

21 |

VMT- 87 |

0.75 |

0.55 |

3000 |

1 |

150 |

227 |

232 |

200 |

205 |

10 |

23 |

68 |

200 |

279 |

596 |

218 |

162 |

155 |

26 |

VMT- 89 |

1.00 |

0.75 |

3000 |

1 |

150 |

227 |

232 |

200 |

205 |

10 |

23 |

68 |

200 |

279 |

596 |

218 |

162 |

155 |

27 |

VMT- 84 |

0.50 |

0.37 |

3000 |

3 |

150 |

230 |

233 |

204 |

204 |

10 |

23 |

68 |

170 |

250 |

596 |

195 |

162 |

168 |

20 |

VMT- 86 |

0.75 |

0.55 |

3000 |

3 |

150 |

227 |

232 |

200 |

205 |

10 |

23 |

68 |

200 |

279 |

596 |

218 |

162 |

155 |

22 |

VMT- 88 |

1.00 |

0.75 |

3000 |

3 |

150 |

227 |

232 |

200 |

205 |

10 |

23 |

68 |

200 |

279 |

596 |

218 |

162 |

155 |

23 |

General Tolerance ± 0.25 % Dimensions, details etc. are subject to change as the quality of machines is improved constantly.