OUR DEVELOPMENTS

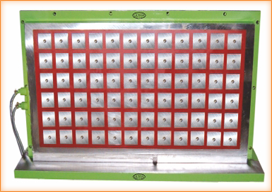

UL-813 "Ultra" Radial Pole EPM Chuck

Features:

- Continuous electricity is not required. 100% safe is used.

- Power for all poles transferred to big rings / plates to hold the job firmly.

- Assembled with power full magnets. So heavy cut can take.

- Poles individually magnetized for full loading power.

Application :

- Use in vertical and horizontals turning of lathhes.

- Radially moveable location blocks will help to position and secure work pieces. This is also necessary for clearance off the cutting tool or wheel.

UL-813 "Ultra" Radial Pole EPM Chuck

Feature:

- Continuous electricity is not required. 100% safe is used.

- Power for all poles transferred to big rings / plates to hold the job firmly.

- Assembled with power full magnets. So heavy cut can take.

- Poles individually magnetized for full loading power.

Application:

-

1. Use in vertical and horizontals turning of lathhes.

- Radially moveable location blocks will help to position and secure work pieces. This is also necessary for clearance off the cutting tool or wheel.

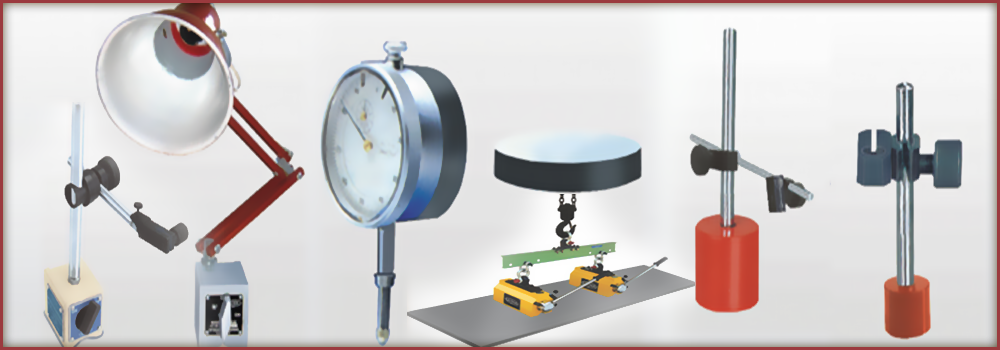

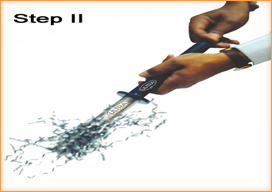

UL-814 "Ultra" Magnetic Stick On Off Type

Feature:

- Eaily clean up sharp edged drill chips screw and other metal parts.

- Items are safely ejected by Pulling the back sideknob.

- Ideal for hard to reach space.

- Used in all fabrication shops and machine shops.

- No requirement of hand contact with scrap to handle, so safe in use.

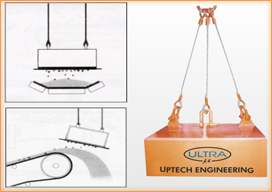

UL-819 "Ultra" Electro Magnetic Sheet Lifter

Feature:

- Electro Magnetic Lifter is design with the consideration of all industrial safety knob, therefore they are very compact, light weight, high strength and very reliable safe in use.

- Electro Magnetic Lifter are work on Electricity & require 220V or 415V supply.

- Electro Magnetic Lifter is used with combinations of various magnets. At fixed structure with provision of chain. So this will help to handle pain as well as bend sheet. In short it will take care of bendness of sheet.

- Inching feature or variable power knob is provided, it ensures that single plate will be fitted.

- Lamp block - displays the system presents.

Appliction:

- It is use on flame cutting machine, plazma cutting machine and water jet cutting machine.

- It is useful for handling small as well as large plates.

- Controller is having optional facility of battery back up which helps to keep magnet on for 15 mins.

Design:

- Designing of EPM Plate Lifter Depends upon maximum and minimum size of plate (length X width X height).

- Crane Capacity

- Weight of Plates.

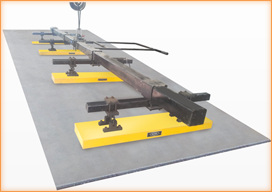

UL-818 "Ultra" Electroperm Magnetic Lifter For Plate Handel

Feature:

- EPM lifting is designed with the consideration of all industrial safety knobs. Therefore they are very compact light weight hig strength and very reliable and safe in use.

- Electro Perm Magnetic Lifter is combination of permanent as well as electro magnet power which is required to clamp the job or declamp the job.

- Lifted plate will not failed down even electric power failed because EPM LIFTER requires power only for holding the plates and declamping the plates. So it is 100% safe for handling the plates.

- Continuous electricity is not required so it having advantage of saving electricity over conventional electromagnetic lifter.

- Electro permanent magnetic lifter is used with combination of various magnets. At fix structure with provision of chain. So this will help to handle pain as well as bend sheets. In short it will take care of bendness of plates.

- Safety interlock key ro magnetized / demagnetized. Two buttons are to be press simultaneously with help to avoid chance of accident.

- "Inching" feature - when the magnets is switch ON, it might lift more than a single plate. Inching operation reduces the magnetic power supply such that additional plates, if lifted are dropped. This is used to make sure that only one palte is handled at time.

- Lamp Block - Displays the system present state.

Application:

- Ideal for handling single plates in stockyards.

- Most effective in ship building industry

- It is use on flame cutting m/c , plazma cutting m/c and water jet cutting m/c.

- It is useful for handling small as well as large plates.

- EPM Lifter is design as per customer plate sizes.

- Controller is having special facility of selector switch help for lifting small size sheets and large plates.

- It is the EPM lifting system is very suitable with EOT / GANTRY / MOBILE crane etc.

Optional Units:

- Radio Remote Control - Operates from a convenient distance all the function i.e. MAG / DEMAG / Inching.

- ADPREM- Accidental Demagnetization Prevention Mechanism. Disable the Demagnetization cycle when carrying load.

Design:

- Designing of EPM Plate LIfter depends upon minimum and maximum size of plate (length X weight X thickness).

- Crane capacity.

- Weight of plates.

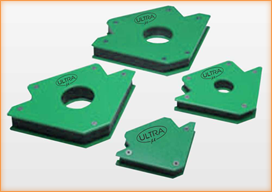

UL - 810 - Adjustable Trisquare Permanent Magnetic

- Sturdy & simple aluminium body.

- Variable angle setting.

- To suitable for welding marketing & inception.

- Arm hold sheet due to powerful magnet.

UL - 811 - Trisquare Permanent Magnetic

- Aluminium body with fixed right angle.

- Keeps hands free during welding of two sheets.

- Suitable for right angel.

- To used in fabrication & welding.

- Used in machine shop for marketing inspection or welding.

UL - 812 - Multiple Angle Setup

- Versatile Multi Titular Designs.

- The Magnet is very powerful.

- Can be hold or sent to 45 to 90 degree.

- Magnet is handling very easy.

- Useful for welding or soldering operation.

UL - 819 - EPM Chuck for Horizontal Machining

- EPM chuck is designed in such a way that it is very useful for horizontal machining centers. It is also useful in conventional machining for horizontal milling operation.

- As electro permanent magnetic (EPM) principle is used continuous electricity with pallet clamping.

- Easily integrated with pallet clamping.

- Manufactured as per customers requirement.

UL - 816 - Suspension Magnet

- Most effective for removal at Tramp iron from materials carried over conveyors.

- It is suspended on the conveyor helf.

- It is mostly suitable in cool mines, food processig domestic watse cycling plant and material processing Indl. etc.

- Suspension magnet works on permanent magnetic principle and requires manual cleaning.

- Suspension magent is designed depending upon customer requiremnt.

Contact Us

UPTECH ENGINEERING

Contact Person- Mr. B. R. Shah Mob: 91-9881075004,

Address : Gat No. 274,Nanekarwadi, Pune - Nasik Highway, Chakan,Tal. Khed

Dist. Pune - 410501,(M.S.) India.

Ph: 91-2135-325004,325554, 306981,

Fax: 91-2135-306982

E-mail: uptechpune1@gmail.com, uptechpune@yahoo.com, uptechengg@yahoo.com