Product Page 7

Features:

- These angle plates are invaluable for accurate work in Tool room, right angle machinery & grinding.

- Made from single piece high quality alloy steel.

- Accuracy for Square ness, Flatness & Parallelism is within 0.005mm upto L & within 0.010mmm upto 300L.

- M6 & M8 tapped holes or slots are provided for clamping.

- Harness -60 ± 2 Rc.

| Sr. No. |

Cat No. |

Size(mm) |

| 1 |

UL-30901 |

115 X 150 X 150 |

| 2 |

UL-30902 |

150 X 150 X 150 |

| 3 |

UL-30903 |

150 X 150 X 225 |

| 4 |

UL-30904 |

115 X 225X 300 |

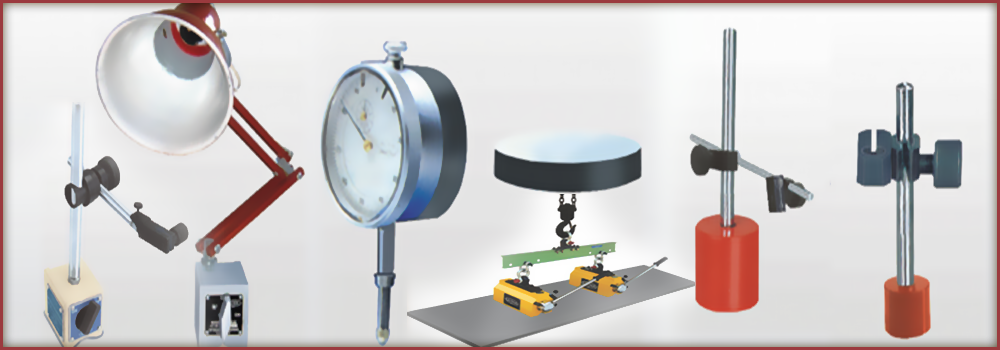

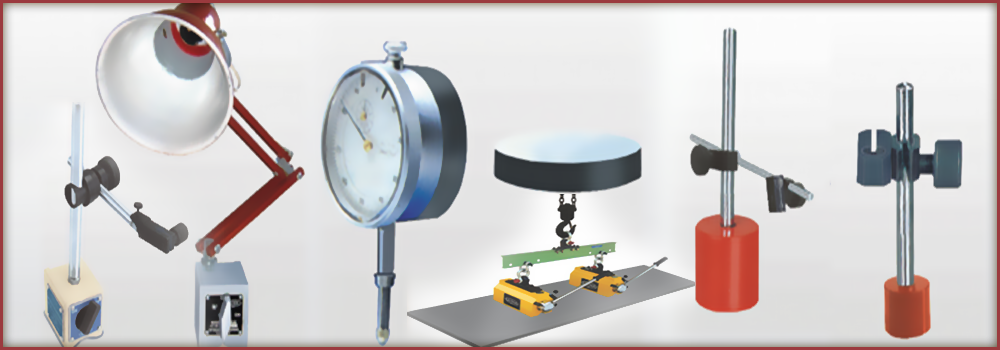

Features:

- Work holding device for conventional & CNC milling m/c.

- Cold device as ir doesn't require power continuously except for short period of activation & deactivation.

- Suitable for light milling i.e. 3-6 mm depth of cut at recommended speed & feed.

- Maximum material removal is possible.

- Economaical for operation & maintenance.

- No accidents due to power failure.

- Slippering force is 2.5 - 3.5 kg/cm2.

| Sr. No. |

Cat No. |

Size(mm) |

| 1 |

UL-71901 |

600L X 300W X 80H |

| 2 |

UL-71902 |

750L X 300W X 90H |

| 3 |

UL-71903 |

1000L X 300W X 90H |

| 4 |

UL-71904 |

1500L X 300W X 90H |

| 5 |

UL-71905 |

600L X 400W X 80H |

| 6 |

UL-71906 |

750L X 400W X 90H |

| 7 |

UL-71907 |

1000L X 400W X 90H |

| 8 |

UL-71908 |

1500L X 400W X 90H |

| 9 |

"ULTRA" CONTROL UNIT WITH VARIABLE SUPPLY |

| 10 |

"ULTRA" POLE EXTENTION BLOCK |

| 11 |

SPECIAL"ULTRA"POLE EXTENTION BLOCK |

| 12 |

"ULTRA"SPRING POLE EXTENTION BLOCK |

Features:

- Work holding device for milling machines.

- Cold device as it doesn't require power continuously except for short period of activation & deactivation.

- Suitable for light milling i.e. 1-3 mm depth of cut at recommended speed & feed.

- Maximum material removal is possible.

- Economical for operation & maintenance.

- No accidents due to power failure.

- Slippering force is 2.5 - 3 Kg/cm 2.

- Vertical lifting force is 35-40 kg/cm 2.

- Variable supply unit to vary power which helps in alignment of jobs.

- Chuck is tested for slippering force, waterproof test, temperature rise test, electrical & demagnetizing tests.

- Good quality & standard electrical accessories.

- We also manufacture special chucks to suit individual requiremnt.

| Sr. No. |

Cat No. |

Size(mm) |

| 1 |

UL-71801 |

500L X 200W X 80H |

| 2 |

UL-71802 |

600L X 200W X 80H |

| 3 |

UL-71803 |

600L X 250W X 80H |

| 4 |

UL-71804 |

600L X 300W X 80H |

| 5 |

UL-71805 |

600L X 400W X 80H |

| 6 |

UL-71806 |

750L X 250W X 90H |

| 7 |

UL-71807 |

750L X 300W X 90H |

| 8 |

UL-71808 |

1000L X 250W X 90H |

| 9 |

"ULTRA"CONTROL UNIT WITH VARIABLE SUPPLY |

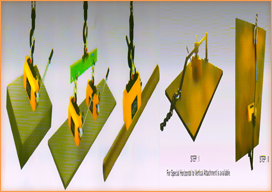

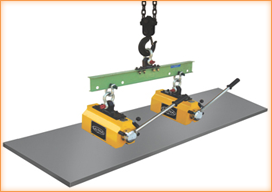

Features:

- Used for lifting & handling of steel plates, heavy plates and castings as well as heavy round or cylindrical parts.

- The 1:3.5 safety factor of the recommended load of the test load ensures use at optimal working conditions even with substantial air gaps & surface conditions.

- Compact design, strong magnetic pull, total work safety.

- Easy operated lever for ON-OFF.

- Spring loaded block at side for safety features.

- Suitable for Flat & Round Jobs.

- No damage on job during operation.

| Sr. No. |

Cat No. |

Size(mm) |

Lifting Capacuty |

Testing Capacuty |

Weight |

| 1 |

UL-80500 |

85L X 60W X 75H |

100 kg |

350 kg |

3kg |

| 2 |

UL-80501 |

170L X 85W X 105H |

200 kg |

700 kg |

9kg |

| 3 |

UL-80502 |

170L X 85W X 105H |

250 kg |

875 kg |

9kg |

| 4 |

UL-80503 |

230L X 85W X 105H |

300 kg |

1050 kg |

14kg |

| 5 |

UL-80504 |

230L X 85W X 105H |

450 kg |

1575 kg |

25kg |

| 6 |

UL-80505 |

290L X 90W X 125H |

600 kg |

2100 kg |

25kg |

| 7 |

UL-80506 |

320L X 120W X 150H |

700 kg |

2450 kg |

36kg |

| 8 |

UL-80507 |

365L X 150W X 180H |

1000 kg |

3500 kg |

80kg |

| 9 |

UL-80508 |

480L X 160W X 180H |

1500 kg |

5150 kg |

125kg |

| 10 |

UL-80509 |

490L X 230W X 250H |

2000 kg |

7000 kg |

170kg |

Features:

- Work holding device for surface grinding machines.

- Each pole is having separate coil as such very strong & even magnetic flux is generated.

- Accuracy as per IS : 8710 - 1978.

- Magnetic pull is 30 - 50% more then IS specification.

- Mag - D - Mag with variable control unit allows to neutralize the residual magnetism precisely, using a microprocessor based control circuitry.

- Variable supply to vary power which helps in alignment & removing of warpages of thin jobs.

- Chuvk is tested for slippering force, waterproof test, temperature rise test, electical & demagnetizing tests.

- Also avaiable in Longitudinal poles.

- We also manufacture special chucks to suit individual requirements.

- Good quality & standard electrical accessories.

| Cat No. |

Jaw Lenght(mm) |

Jaw Opening(mm) |

| UL-30701 |

38 |

17 |

| UL-30702 |

50 |

25 |

| UL-30703 |

75 |

40 |

| UL-30704 |

100 |

65 |

| UL-30705 |

125 |

90 |

| UL-30706 |

150 |

125 |

| UL-30707 |

200 |

150 |

| UL-30708 |

250 |

200 |

| UL-30709 |

300 |

250 |

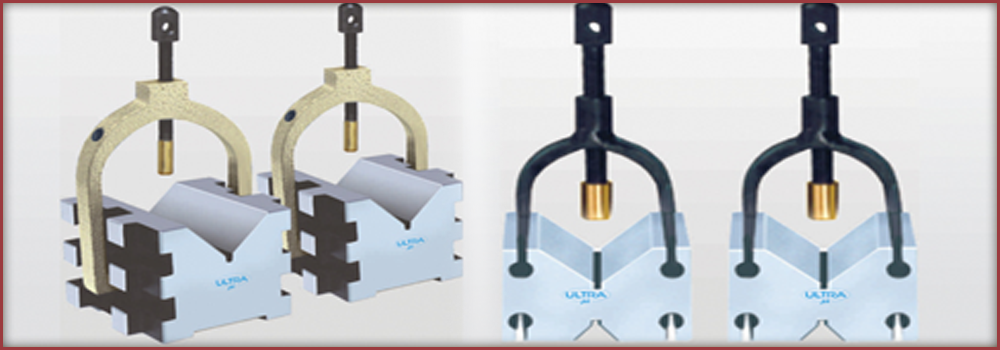

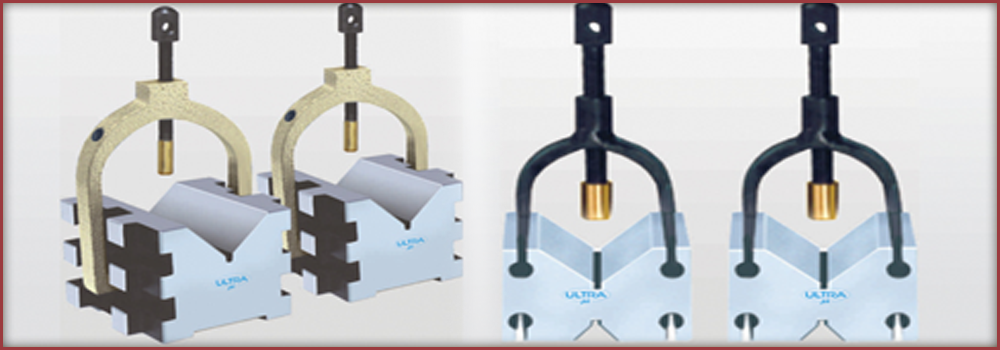

Features:

- Holding device for surface grinding machine, tool & cutter grinder, spark erosion machines.

- Accuracy as per IS: 4816 - 1987.

- Poles individually magnetised for full loading power.

- Magnetic pull is 40-70% more than IS specification.

- Bottom plate has suitable extension to clamp on table.

- Easy operated ON-OFF lever.

| Sr. No. |

Cat No. |

Size(mm) |

Slot(mm) |

Range(mm) |

| 1 |

UL-50501 |

72L X 68W X 35H |

14 x 2 |

Ø25-Ø70 mm |

| 2 |

UL-50502 |

76L X 75W X 35H |

14 x 2 |

Ø35-Ø90 mm |

| 3 |

UL-50503 |

80L X 75W X 40H |

14 x 2 |

Ø400-Ø105 mm |

| 4 |

UL-50504 |

100L X 85W X 40H |

14 x 2 |

Ø40-Ø125 mm |

| 5 |

UL-50505 |

120L X 90W X 40H |

14 x 2 |

Ø110-Ø180 mm |

Contact Us

UPTECH ENGINEERING

Contact Person- Mr. B. R. Shah Mob: 91-9881075004,

Address : Gat No. 274,Nanekarwadi, Pune - Nasik Highway, Chakan,Tal. Khed

Dist. Pune - 410501,(M.S.) India.

Ph: 91-2135-325004,325554, 306981,

Fax: 91-2135-306982

E-mail: uptechpune1@gmail.com, uptechpune@yahoo.com, uptechengg@yahoo.com