Product Page 2

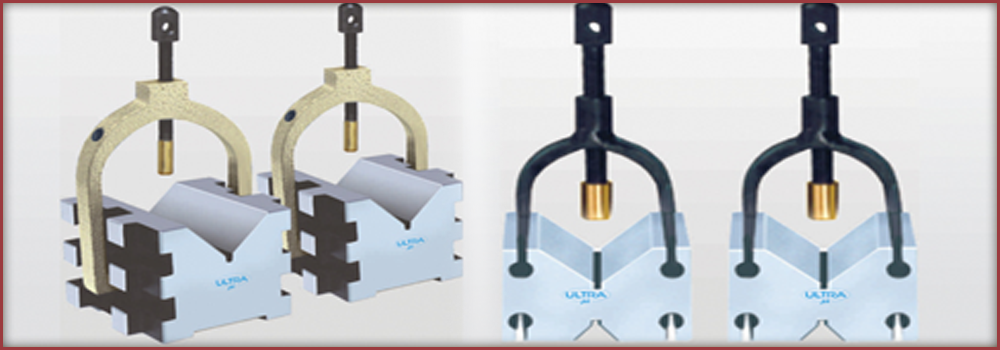

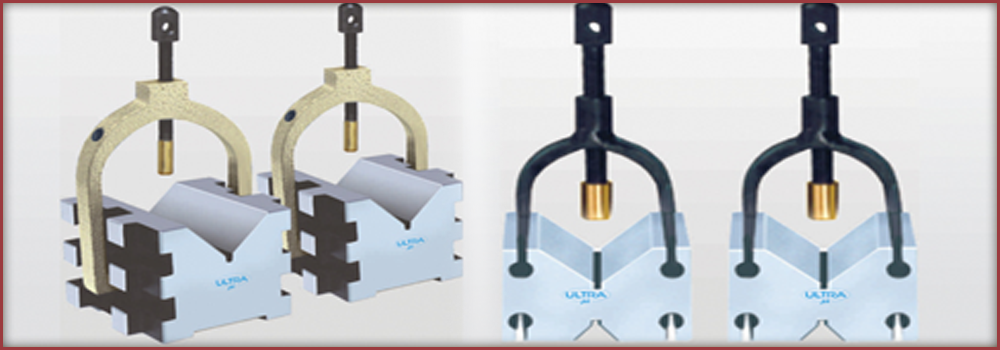

Features:

- Used for Grinding, Light Milling, Drilling & inspection of round & square jobs.

- Accuracy for flatness, squareness & parallelism within ±0.005mm

- Tenon slot (16X3) at bottom can be used for clamping on machine bed.

- Hardness 60±2 Rc.

- Entire top of V is accessible due to unique design.

- Supplied in perfect matched pair.

| Cat No. |

Size(mm) |

Range(mm) |

| UL-10401 |

75L X 120 W X 60H |

Ø3-Ø50 |

| UL-10402 |

100L X 150 W X 75H |

Ø5-Ø75 |

| UL-10403 |

125L X 200 W X 100H |

Ø5-Ø100 |

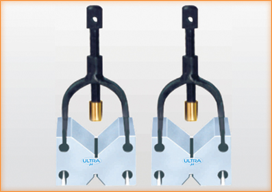

Features:

- Used for Grinding, Light Milling, Drilling & inspection of round & square jobs.

- Accuracy for flatness, squareness & parallelism within ±0.003mm

- It can be used on the base, ends & sides.

- Hardness 60±2 Rc & supplied in perfect matched pair.

- Sturdy clamps for better clamping of jobs.

- End face grinding, right angle with sides is possible.

| Cat No. |

Size(mm) |

Range(mm) |

| UL-11301 |

40L X 35 W X 45H |

Ø3-Ø25 |

| UL-11302 |

55L X 40W X 55H |

Ø3-Ø40 |

<| UL-11303 |

65L X 45 W X 70H |

Ø5-Ø50 |

<| UL-11304 |

90L X 70 W X 125H |

Ø5-Ø60 |

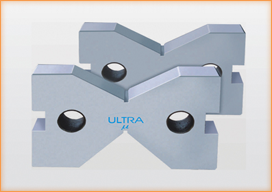

Features:

- Used for Griding, Light Miling, Driling & inspection of round & square jobs.

- Accuracy ±0.005mm

- Hardness 60±2 Rc

- Supplied in perfect matched pair.

- Top angle is 120o

- Bottom angle 90o

- Suitable for checking of lobbing.

- Sturdy clamps for better clamping of jobs.

| Cat No. |

Size(mm) |

Range(mm) |

| UL-11401 |

45L X 120W X 75H |

Ø9-Ø125 |

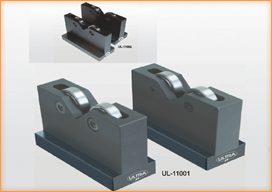

Features:

- used for checking heavy and odd shaped round jobs.

- Perfectly matched pair having accuracy 0.005mm.

- Included angel of rollers is 90o

- Standard bearings are used which are replaceable.

- Jobs don't get damaged due to bearing on top.

- Special sizes suitable for different diameter manufactured on request.

| Cat No. |

Size Top |

Size Bottom |

Height |

Range |

Load Capacity |

| UL-11001 |

150L X 40W |

150L X 80W |

100H |

Ø3-Ø55 |

1000Kgs |

| UL-11002 |

150L X 22W |

150L X 60W |

100H |

Ø25-Ø70 |

500Kgs |

| UL-11003 |

230L X 60W |

230L X 100W |

150H |

Ø70-Ø200 |

1000Kgs |

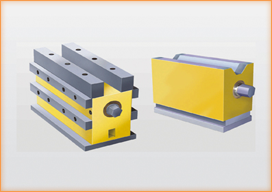

Features:

- All surfaces are hardened & ground for cat no. 80701.

- Suitable for conventional & CNC Miling.

- Suitable for milling 1 to 3mm.

- Economical for operations & maintainence.

- No accidents due to power failure.

- Slippering force 2.5 kg/cm2

- Vertical lifting force is 35 -40 kg/cm2

| Cat No. |

Size(mm) |

| UL-80701 |

230L X 115W X 160H |

| UL-807021 |

175L X 85W X 130H |

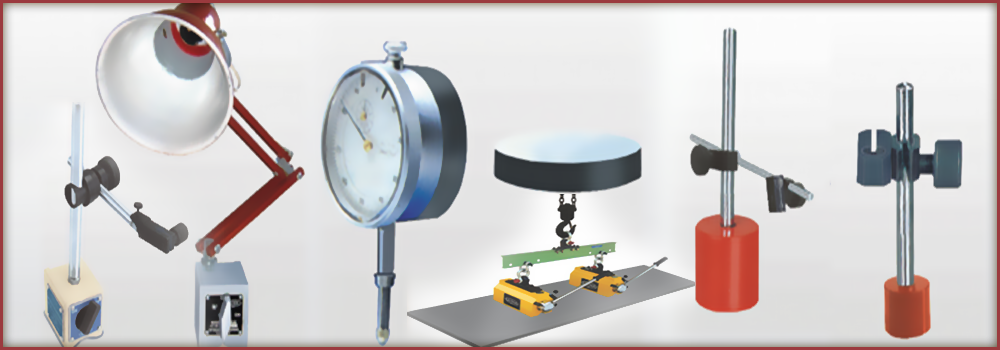

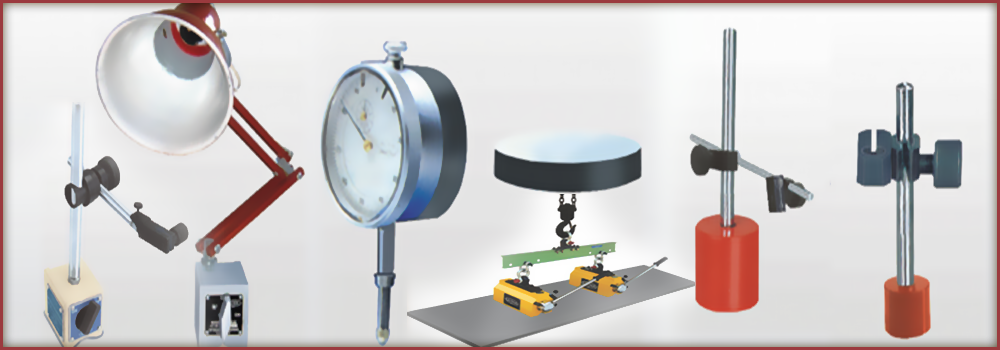

Features:

- Used for Grinding, Light Milling, Drilling & inspection of round & square jobs.

- Accuracy for Parallelism is within ±0.005mm.

- Provided with On-Off switch except for 1" block.

- Supplied in perfect matched pair.

- hardened strips provided in hard pair.

| Series No. |

Cat No. |

Size(mm) |

| 1 |

UL-20101 Soft |

25L X 25W X 25H |

| 2 |

UL-20102 Soft |

75L X 56W X 60H |

| 3 |

UL-20103 Soft |

100L X 70W X 70H |

| 4 |

UL-20104 Soft |

150L X 70W X 85H |

| 5 |

UL-20102 Hard |

75L X 56W X 60H |

| 6 |

UL-20103 Hard |

100L X 70W X 70H |

| 7 |

UL-20104 Hard |

150L X 70W X 85H |

Features:

- Used for holding flat & round jobs during Inspection, Grinding and Welding

.

- Accuracy for Flatness, Squareness & Parallelism within 0.005mm.

- ON-OFF is done by rotation of handle.

- Provides angle reference of 45o, 90o and 120o.

- Strong magnetic pull on all ground portions.

- Hardened strips provided on all working surfaces in hard blocks for wear resistance.

| Cat No. |

Size(mm) |

Pull(on"V") |

Pull(On plain) |

| UL-20101 Soft |

110L X 110W X 140H |

100kg. |

125kg. |

<| UL-20102 Hard |

110L X 110W X 140H |

75kg. |

100kg. |

Features:

- Small & Compact size.

- Powerful holding of the magnet on the machine table.

- Easy holding of the diamond dresser.

| Cat No. |

Size(mm) |

Magnetic Pull |

| UL-61301 |

56L X 70W X 70H |

70kg. |

Features:

- Small & compact size.

- Easy holding of the diamond dresser.

- To be used on grinding machine with magnetic chuck.

- Hardened & ground.

| Cat No. |

Size(mm) |

| UL-61401 |

70L X 70W X 50H |

Contact Us

UPTECH ENGINEERING

Contact Person- Mr. B. R. Shah Mob: 91-9881075004,

Address : Gat No. 274,Nanekarwadi, Pune - Nasik Highway, Chakan,Tal. Khed

Dist. Pune - 410501,(M.S.) India.

Ph: 91-2135-325004,325554, 306981,

Fax: 91-2135-306982

E-mail: uptechpune1@gmail.com, uptechpune@yahoo.com, uptechengg@yahoo.com