Product Page 4

Features:

- Used for holding jobs together.

- Made from hardened steel & precision ground for parallelism.

- Designed for maximum strength & rigidity.

- A retaining strip hold loose job in alignment when clamp is tightened or loosened.

- The ends of the jaws are rounded to permit clamping under shoulder or in recess.

- Also available in stainless steel

| Cat No. |

Jaw Length(mm) |

Jaw Opening(mm) |

| UL-30701 |

38 |

17 |

| UL-30702 |

50 |

25 |

| UL-30703 |

75 |

40 |

| UL-30704 |

100 |

65 |

| UL-30705 |

125 |

90 |

| UL-30706 |

150 |

125 |

| UL-30707 |

200 |

150 |

| UL-30708 |

250 |

200 |

| UL-30709 |

300 |

250 |

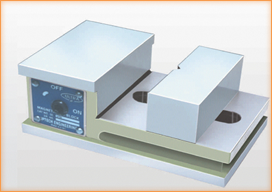

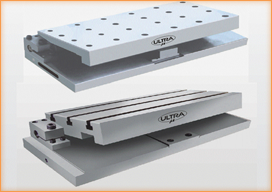

Features:

- Used for holding flat squared & round jobs.

- Accuracy for flatness, squareness & parallelism within ±0.005mm.

- "V" on moveable jaw failities end face grinding.

- Job is clamped only by resting between fixed & moveable jaw and operating On-Off switch.

- ON-OFF facility by allen key.

| Cat No. |

Size(mm) |

Jaw-Holding Area(mm2) |

| UL-20401 |

110L X 180W X 75H |

100 X 65 |

| UL-20402 |

160L X 225W X 90H |

150 X 75 |

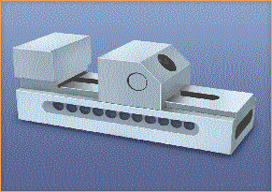

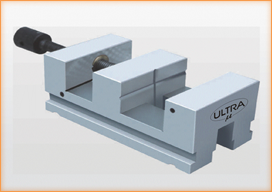

Features:

- Used for holding the jobs, spark erosion operation, right angle grinding & light machining.

- Made from high quality alloy steel.

- Accuracy for squareness, flatness & parallelism within ±0.005mm.

- Jaw pressure on work piece is forward and downward for repeatable positioning & maximum holding power.

- All sides can be used as reference.

- Hardness 60 ± 2 RC & tempered.

- "V" on moveable jaw for better ripping of round jobs.

| Cat No. |

Size(mm) |

Jaw Opening(mm) |

| UL-31001 |

150L X 48W X 60H |

0-75 |

| UL-31002 |

180L X 63W X 70H |

0-90 |

| UL-31003 |

200L X 73W X 80H |

0-100 |

| UL-31004 |

235L X 96W X 96H |

0-130 |

Features:

- Made from stainless steel.

- Used for holding the jobs, spark erosion operation, right angle grinding & light machining.

- Accuracy for Squareness, flatness & parallelism within ±0.005mm.

- Jaw pressure on work piece is forward & downward for repeatable positioning & aximum holding power.

- All sides can be used as reference.

- Hardness 55 ± 2 RC.

- "V" on moveable jaw for better gripping of round jobs.

| Cat No. |

Size(mm) |

Jaw Opening(mm) |

| UL-3501 |

150L X 48W X 60H |

0-75 |

| UL-3502 |

180L X 63W X 70H |

0-90 |

| UL-3503 |

200L X 73W X 80H |

0-100 |

| UL-3504 |

235L X 96W X 96H |

0-130 |

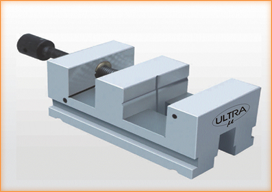

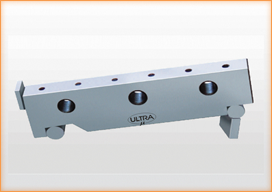

Features:

- Used for holding the jobs, right angle grinding & light machining.

- Made from high quality alloy steel.

- Accuracy for squareness, flatness & parallelism within ±0.005mm

- Hardness 60 ± 2 RC.

- Wear Plate at bottom to prevent lifting of jaw.

- Clamping screw with square thread & gun metal nut.

- Tenon at bottom to allow easy alignment with machine bed.

| Sr.No. |

Cat No. |

Size(mm) |

Jaw Height(mm) |

Opening(mm) |

Step in Jaw(mm) |

| 1 |

UL-31101 |

150L X 50W X 50H |

22 |

0-70 |

3 X 2 |

| 2 |

UL-31102 |

175L X 60W X 55H |

28 |

0-80 |

3 X 3 |

| 3 |

UL-31103 |

190L X 75W X 65H |

32 |

0-85 |

4 X 3 |

| 4 |

UL-31104 |

210L X 95W X 75H |

38 |

0-100 |

5 X 3 |

Features:

- Made from stainless steel.

- Used for holding the jobs, right angle grinding & light machining.

- Accuracy for squareness, flatness & parallelism within ±0.005mm.

- Hardness 55 ± 2 RC.

- Wear plate at bottom to prevent lifting of jaw.

- Hardened clamping screw with square thread & gun metal nut.

- Tenon at bottom to allow easy alignment with machine bed.

| Sr.No. |

Cat No. |

Size(mm) |

Opening(mm) |

| 1 |

UL-31701 |

150L X 50W X 50H |

0-70 |

| 2 |

UL-31702 |

175L X 60W X 55H |

0-80 |

| 3 |

UL-31703 |

190L X 75W X 65H |

0-85 |

| 4 |

UL-31704 |

210L X 95W X 75H |

0-95 |

Features:

- Used for precision measurement, setting of angles, right angle grinding & light machining.

- Made from high quality alloy steel.

- Accuracy for squareness, flatness & parallellism is ±0.005mm upto 200L & 0.010mm upto 350L.

- Angular accuracy within ±5 seconds.

- Centre distance between rollers is within ±0.005mm.

- Hardness 60 ± 2 RC & tempered.

| Cat No. |

Size(mm) |

C.D(mm) |

Opening(mm) |

| UL-31201 |

190L X 65W X 85H |

100 |

80 |

| UL-31202 |

235L X 75W X 100H |

150 |

100 |

| UL-31203 |

265L X 95W X 105H |

150 |

125 |

| UL-31204 |

290L X 120W X 145H |

200 |

145 |

| UL-31205 |

310L X 140W X 145H |

200 |

160 |

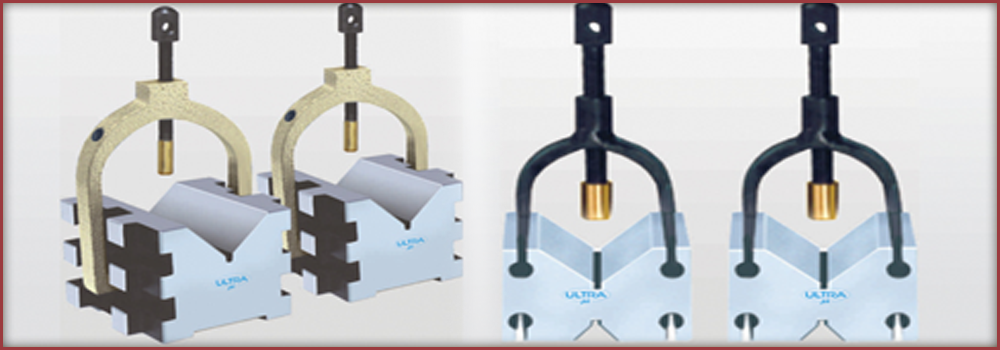

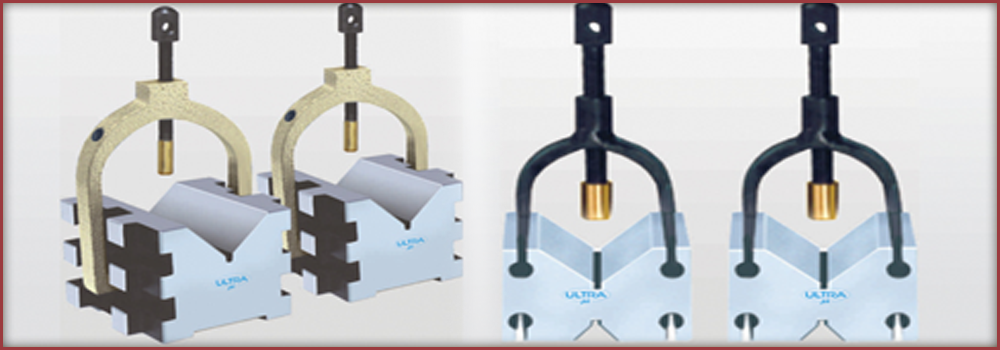

Features:

- Used for precision measurement, setting of angles.

- Made from high quality alloy steel.

- Accuracy for squareness, flatness & parallellism is ±0.005mm upto 200L & 0.010mm upto 350L.

- Centre distance between rollers is within ±0.003mm.

- Hardness 60 ± 2 RC & tempered.

- Accuracy as per IS standards IS - 5359 - 1987.

| Cat No. |

Size(mm) |

C.D(mm) |

| UL-31301 |

130L X 20W X 40H |

100 |

| UL-31302 |

230L X 30W X 40H |

200 |

| UL-31303 |

345L X 40W X 50H |

300 |

Features:

- Used for precision measurement, setting of angles.

- Made from high quality alloy steel.

- Accuracy for squareness, flatness & parallellism is ±0.005mm upto 200L & 0.010mm upto 350L.

- Centre distance between rollers is within ±0.003mm.

- Hardness 60 ± 2 RC & tempered.

- Top surface is provided with magnet.

- Accuracy as per IS standards IS - 5359 - 1987.

| Cat No. |

Size(mm) |

C.D(mm) |

| UL-31304 |

130L X 20W X 40H |

100 |

| UL-31305 |

230L X 30W X 40H |

200 |

| UL-31306 |

345L X 40W X 50H |

300 |

Features:

- Used for precision measurement, setting of angles, utilizing slip gauige & light machining.

- Ideal for high accuracy grinding operations.

- Accuracy for squareness, parallelism & flatness is 0.005mm upto 200L & 0.010mm upto 450L.

- Positive locking at all angles without any distortion.

- Angle can be set within ±5 seconds.

- Center distance between rollers is within 0.005mm.

- Made from high quality alloy steel.

- Hardness 58 ± 2 RC & tempered.

- Firm clamp to reduce possibility of distortion.

- M6 & M8 tapped holes for job clamping.

- Low hight for more wheel clearence.

- Sloted signe table on Request.

- Also manufacture as per customers requirement.

| Sr. No. |

Cat No. |

Size(mm) |

C.D(mm) |

Inclination (in degree) |

| 1 |

UL-40101 |

150L X 120W X 65H |

70 |

0-45 |

| 2 |

UL-40102 |

250L X 150W X 65H |

100 |

0-45 |

| 3 |

UL-40103 |

300L X 150W X 65H |

100 |

0-45 |

| 4 |

UL-40104 |

450L X 150W X 65H |

100 |

0-45 |

Contact Us

UPTECH ENGINEERING

Contact Person- Mr. B. R. Shah Mob: 91-9881075004,

Address : Gat No. 274,Nanekarwadi, Pune - Nasik Highway, Chakan,Tal. Khed

Dist. Pune - 410501,(M.S.) India.

Ph: 91-2135-325004,325554, 306981,

Fax: 91-2135-306982

E-mail: uptechpune1@gmail.com, uptechpune@yahoo.com, uptechengg@yahoo.com