- Home

- Applications

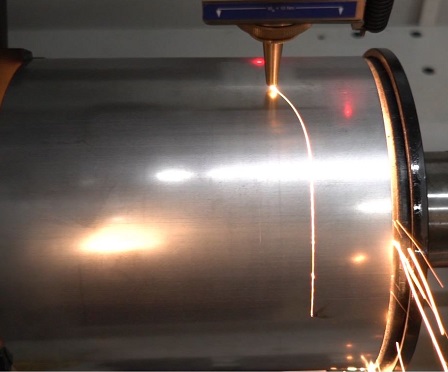

Laser Cutting

In the last four decades, laser cutting has not just gained immense importance but has also become an indispensable part of the manufacturing world. From product manufacturing to fabrication and beyond, laser, has become an industry required daily by automotive, switch gear, earth moving equipment and ship building industry without any limits. You can find laser products almost everywhere. Laser is used for cutting almost all metals & plastics, performing eye surgeries, and whatnot.

Due to ongoing developments in laser which is improving their efficiency and power, new methods and processes based on laser are being discovered. Total approach of manufacturing industries has changed due to invention of laser. The Industries have benefited by application of laser technology in place of conventional tools.

But still, there is a lot of information about laser technology that most people are unaware of. In this article, we will discuss everything about laser cutting, from its definition to its uses and benefits. Keep reading!

In the last four decades, laser cutting has not just gained immense importance but has also become an indispensable part of the manufacturing world. From product manufacturing to fabrication and beyond, laser, has become an industry required daily by automotive, switch gear, earth moving equipment and ship building industry without any limits. You can find laser products almost everywhere. Laser is used for cutting almost all metals & plastics, performing eye surgeries, and whatnot.

Due to ongoing developments in laser which is improving their efficiency and power, new methods and processes based on laser are being discovered. Total approach of manufacturing industries has changed due to invention of laser. The Industries have benefited by application of laser technology in place of conventional tools.

But still, there is a lot of information about laser technology that most people are unaware of. In this article, we will discuss everything about laser cutting, from its definition to its uses and benefits. Keep reading!

What Is Laser Cutting?

Laser Cutting is a process of cutting profiles on the materials. It is a very effective technology that is not only used for industrial purposes but is also used for prototype developers and commercial artists.

In general, Laser is a tool with sharp focused high power density source of energy. Being light, it can be conveyed onto workpiece by optical fibre cables, lenses and mirrors.

It does not have any weight and does not exert any pressure on the job / workpiece. Laser cutting is non contact type process. So, no forceful clamping is necessary.

The job can be as thin as 10 microns or as thick as 25 mm or more.

Also, because of its unique properties, it can process the jobs from close ( < 1mm) or from distance (< 300 mm).

It is used in situations where processing is to be done on very difficult to approach locations where traditional tools cannot reach.

Being zero weight, having zero inertia, it can be rapidly positioned or moved just by deflecting mirrors, so it is helpful in reducing cycle times.

Laser cutting is an amazing technology that results in higher efficiency and lower cost.

Applications & Uses of Laser Cutting Machine

As we have already mentioned, laser is an industry without any limits. Below are some of the most popular applications of laser cutting :

Metals

Laser cutting works on a wide range of metals. A laser cutting machine is a highly precise tool that can efficiently make a large number of components such as parts of cars, and more.

It can be used when work piece has lower thickness from

6mm upto 25 mm with higher speed.

Moreover, different types of metals undergo different types of operations in laser cutting. Most of the time, unique shapes such as hydro-formed parts, vehicle frames or parts in spacecraft need laser cutting for higher precision. Note that the results given by laser cutting machines are much better than those given by plasma cutting.

Medical Industry

Laser cutting plays a very important role in the medical industry, where higher precision is required. This technology fulfills the high volume demands of the medical industry by delivering higher accuracy and efficiency. Most medical devices and equipment, including orthopedic devices, surgical equipment, and cardiovascular devices require laser cutting for higher precision.

Engraving and Marking

Engraving and marking is another area where laser technology plays an important role. Laser marking machines are used for marking logos, QR codes, part no.s , traceability on metal, plastic, or wooden articles. A growing number of manufacturers turn to laser technology for cutting and welding.

Benefits of Laser Cutting

Below are the main reasons behind the growing popularity of laser cutting machines :

Highly Versatile : Laser cutting is a very versatile technology when it comes to materials. Laser cutters can work with a wide variety of materials including metals, ceramics, and a many non-metals as well.

Faster & Accurate : Laser cutting is a lot faster and more accurate than other machining processes. This is the reason why many manufacturers use it for mass production.

Less Waste : Laser cutting results in clean and precise cuts without resulting in a lot of scraps. Moreover, the turnaround times is also less with laser machines.

These are just a handful of advantages of laser cutting. It offers many more benefits in terms of accuracy, efficiency, cost, and time.