- Home

- Our Machines

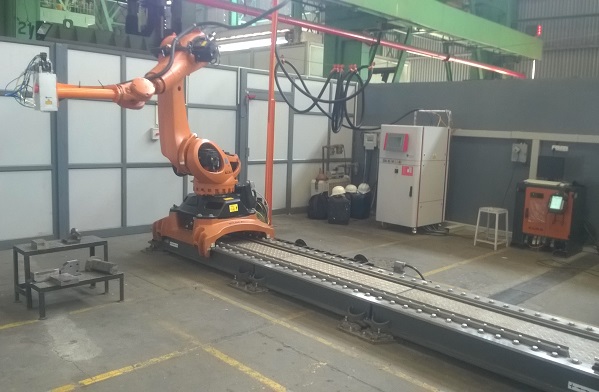

Laser Hardening Machine

Hardening is done on special die' for forming various car BIW parts like side doors, rear door etc. This consists of a KUKA six axis robot of 60 kg payload capacity mounted on linear track which can travel up to 5 meters length. The robot is integrated with a laserline laser LDF 4000-100. The laser hardening process is done with laserline make state of the art OTZ – VR i.e. zoom optics which can be used for variable spot size of 8 x 8 up to 53 x 53 mm.

Hardening is done on special die' for forming various car BIW parts like side doors, rear door etc. This consists of a KUKA six axis robot of 60 kg payload capacity mounted on linear track which can travel up to 5 meters length. The robot is integrated with a laserline laser LDF 4000-100. The laser hardening process is done with laserline make state of the art OTZ – VR i.e. zoom optics which can be used for variable spot size of 8 x 8 up to 53 x 53 mm.

Which materials can be laser hardened?

Laser hardening is suitable for hardenable steels, cast iron etc having at least 0.2% carbon content. However, the maximum achievable hardness is dependent on carbon content, alloying elements as well as part geometries in some cases.

Can we harden already hardened material?

Yes, generally it is possible to laser harden already hardened material.

Which type of lasers are best suitable for laser hardening?

High power Diode lasers, due to their uniform intensity distribution ("Top Hat" beam shape) profile, and excellent wall plug efficiency are best suitable for the process. Also the spot size of the diode laser beam can be adapted to dimensions of the target area to be hardened giving the process very controlled and uniform heat input.