- Home

- Applications

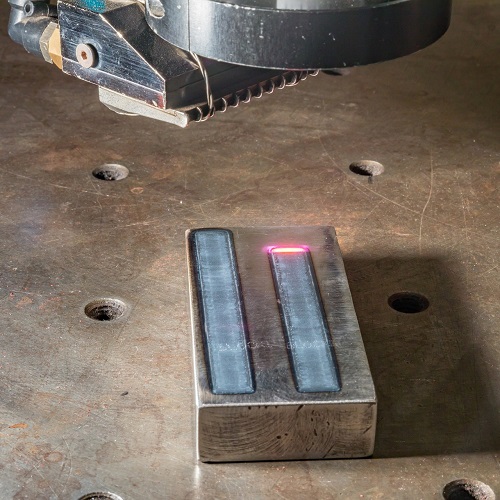

Laser Hardening

What is Laser Hardening?

What is Laser Hardening?

Laser Hardening is a modern method and solves all these problems. It is a case hardening process in which a laser beam is used to heat the surface of the component in a precisely temperature controlled way. Due to high precision, only that part of the component which needs to be hardened is heated, and the bulk of the material acts as the heat sink, producing a self quenching effect.

Distortion is very low or close to nil, so no post processing required. Laser Hardening can also be used as the final process on a finished product.

Applications of Laser Hardening

Laser hardening is used to locally improve wear resistance, hardness and fatigue life of a material. This method is ideal for case hardening, and for complex geometries where precision is critical. It is ideal because minimum heat is transferred to surrounding material.

- Laser Hardening is used in many applications

- Increasing hardness of cutting tools:

- In cutting/ turning tools, the hardness of the tools material must be considerably higher than the hardness of the material workpiece. Laser hardening gives the desired results.

- Transmission components like cams, camshafts, sprockets, gears , racks and pinions etc.

- It has Applications in press forming tools.

- In earth moving equipment, surface is required to have high hardness and abrasion resistance. But using hard material altogether makes it brittle, hence increasing chances of fracture and cracks. Laser hardening is used to harden just the surface with penetration precisely as required, hence, giving advantage of high abrasion and wear resistance without compromising or making the material brittle.