Gallery

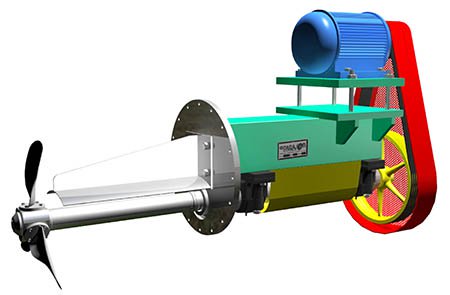

AGITATOR

PARASON has two dedicated modern foundries and two dedicated machine shops attached with a finishing unit to meet customer as well as own captive requirements

PARASON has two dedicated modern foundries and two dedicated machine shops attached with a finishing unit to meet customer as well as own captive requirements

Specia

l Features

- Various Metallurgy to suit each applications.

- Maintenance Free.

- Low Power Consumption.

- Adjustable Blade Angle.

- Inbuilt Dilution Arrangement.

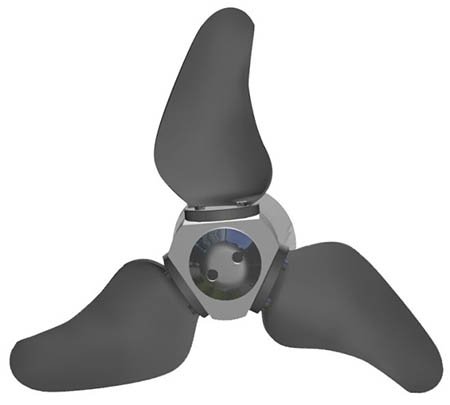

Agitator Blades

PARASON has two dedicated modern foundries and two dedicated machine shops attached with a finishing unit to meet customer as well as own captive requirements

PARASON has two dedicated modern foundries and two dedicated machine shops attached with a finishing unit to meet customer as well as own captive requirements

For efficient mixing

- Effective agitation at low power consumption.

- All wet parts of stainless steel.

- Propeller is equipped with replaceable blades.

- Blade angles are adjustable.

- Guiding plate to increase efficiency (avoids rotation of pulp and reduces power consumption).

For all types of fibers

The PARASON agitators are designed for all kind of fibers in chests, tanks and storage towers up to a consistency of 5% in the propeller area.

History- Making of Parason

Parason started by Dr. C P Desarda (Doctorate in Metallurgy) from BRNO University, Prague, Czech Republic in 1970. Dr. Desarda innovated manufacturing of Refiner.

Parason - Over View

PARASON has installed more than 4000 nos of Disk Refiners, 500 nos Conical Refiners and approx 1600 nos of screens in India and overseas of different size and capacities.

Parason at Aurangabad

Aurangabad city is well connected by all means of transport from all corners across the globe. Aurangabad has good air connectivity too from Delhi, Mumbai and other Metro cities of India.