Gallery

Finedge Refiner Plates

Parason Finedge Milled Bar - Refiner Plates

PARASON Finedge Milled Bar refiner plates are manufactured using CNC technology to provide the maximum uniformity in the refining zone.

PARASON Finedge Milled Bar refiner plates are manufactured using CNC technology to provide the maximum uniformity in the refining zone.

PARASON milled blanks are cast in own foundry as a solid piece to provide uniform hardness throughout. The plates will wear uniformly over time, and with the zero draft angle on the bar, hydraulics are maintained longer.

The PARASON precision CNC Milling manufacturing process provides accurate groove width, which allows finer bar to optimize low intensity applications. Plates life is also maximized by re-grooving which allows 2-3 life cycles.

Parason Finedge Welded Bar - Refiner Plates

PARASON Finedge Welded Bar refiner plates are manufactured using Special Casting & Robot Welding, CNC technology to provide the maximum uniformity in the refining zone.

PARASON Finedge Welded Bar refiner plates are manufactured using Special Casting & Robot Welding, CNC technology to provide the maximum uniformity in the refining zone.

PARASON Finedge Welded Refiner Plates are cast in own foundry to provide uniform hardness throughout and Welded with Special Welding Technology. The plates will wear uniformly over time, and with the zero draft angle on the bar, with high Bar height, with minimum bar width, hydraulics are maintained longer.

The PARASON precision Special Cast, Laser & Weldnig, manufacturing process minimizes groove width variations, which allows finer bar to optimize low intensity applications. Plates life is maximized due to high bar height able to maintain in this technology.

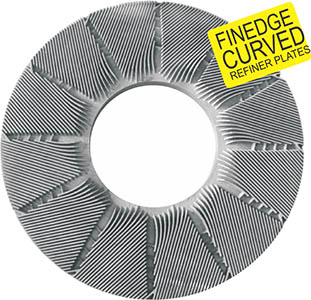

Parason Finedge Curved Bar - Refiner Plates

PARASON Finedge Curved Bar refiner plates are manufactured using Special Casting & CNC technology to provide the maximum uniformity in the refining zone.

PARASON Finedge Curved Bar refiner plates are manufactured using Special Casting & CNC technology to provide the maximum uniformity in the refining zone.

PARASON Finedge Curved Bar refiner plates are special cast in own foundry to provide uniform hardness throughout. The plates will wear uniformly over time and having a longer bar length. The flow of pulp follows the grooves between the bars results in longer residence time. Thus, the result of Finedge Curved bars is more gentle refining action which continuous over a longer time. Curving the refiner bars causes them to function better as a pump. The half dams between sectors further improve the pulp residence time resulting into improved refining.

The PARASON precision Special Casting & CNC manufacturing process provides accurate groove width, which allows finer bar to optimize low intensity applications.

History- Making of Parason

Parason started by Dr. C P Desarda (Doctorate in Metallurgy) from BRNO University, Prague, Czech Republic in 1970. Dr. Desarda innovated manufacturing of Refiner.

Parason - Over View

PARASON has installed more than 4000 nos of Disk Refiners, 500 nos Conical Refiners and approx 1600 nos of screens in India and overseas of different size and capacities.

Parason at Aurangabad

Aurangabad city is well connected by all means of transport from all corners across the globe. Aurangabad has good air connectivity too from Delhi, Mumbai and other Metro cities of India.