Gallery

MC Centrclearner

Working Principles

Parason Medium consistency Centricleaner operates at consistency range of 1.5 to 2 % against normal cleaner range of 0.6 to 1 % consistency. Centricleaner bottles are arranged in planetary system with inlet header at the centre, distributing pulp stock evenly to all centricleaning bottles at constant pressure. Accept of all centricleaner bottles also collected in planetary manner at the centre. Rejects collect in closed loop in the reject header directly connected to reject pump feeding to Secondary stage cleaner. Deareation system also provided for Approach Flow cleaner to remove air from pulp stock.

Parason Medium consistency Centricleaner operates at consistency range of 1.5 to 2 % against normal cleaner range of 0.6 to 1 % consistency. Centricleaner bottles are arranged in planetary system with inlet header at the centre, distributing pulp stock evenly to all centricleaning bottles at constant pressure. Accept of all centricleaner bottles also collected in planetary manner at the centre. Rejects collect in closed loop in the reject header directly connected to reject pump feeding to Secondary stage cleaner. Deareation system also provided for Approach Flow cleaner to remove air from pulp stock.

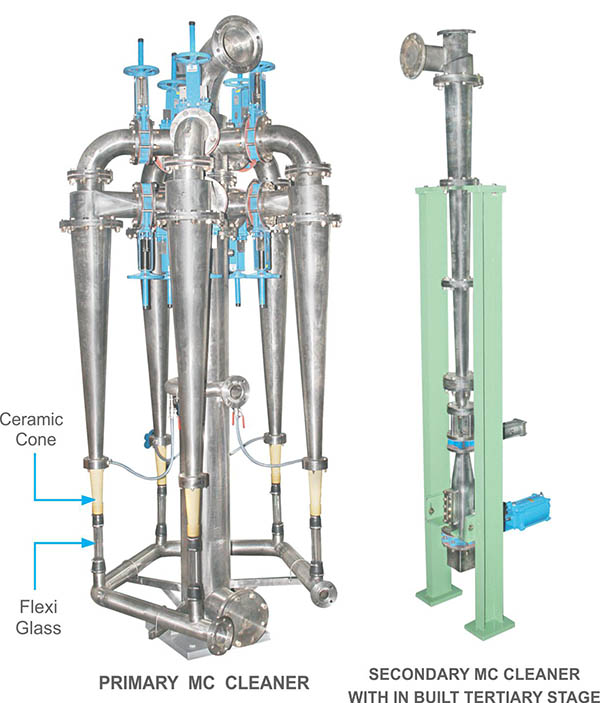

Bottom cone of Primary bottles provided with Ceramic cone for improved life and for efficient separation of heavy contaminates from pulp stock. Flexi glass with quick release fitment provided between bottom ceramic cone and reject header for easy cleaning of nozzles.

Dilution at middle of cone provided to increase centrifugal action at bottom cone increasing efficiency of cleaners. Secondary stage cleaner provided with in Built Tertiary Stage and Auto flushing system in reject chamber for fiber recovery and efficient disposal of heavy contaminates from the system.

Special Features Of “Parason” Mc Centricleaner

- Less Floor Area - Bottles arranged in Planetary design.

- Reduce thickner size up to 50%

- Longer life of bottles - Ceramic bottom cone with dilution nozzle.

- Ceramic cone provided with HDPE cover to avoid damage during

handling. - No Reject nozzle jamming- Flexi glass reject discharge for easy

cleaning. - No Civil Works - Reject collected in header avoiding Reject

tanks. - Power consumption reduced upto 50% in centricleaning.

History- Making of Parason

Parason started by Dr. C P Desarda (Doctorate in Metallurgy) from BRNO University, Prague, Czech Republic in 1970. Dr. Desarda innovated manufacturing of Refiner.

Parason - Over View

PARASON has installed more than 4000 nos of Disk Refiners, 500 nos Conical Refiners and approx 1600 nos of screens in India and overseas of different size and capacities.

Parason at Aurangabad

Aurangabad city is well connected by all means of transport from all corners across the globe. Aurangabad has good air connectivity too from Delhi, Mumbai and other Metro cities of India.