Palletizing Systems

Palletizing is a demanding application of stacking boxes, bags, cases, bottles, and cartons onto pallets as the last step in the assembly line before being loaded onto a shipping truck. Pallet pattern flexibility, tooling flexibility, and cycle time are three major challenges of automated palletizing in today's industry. Kawasaki palletizing systems offer solutions to each of these palletizing challenges.

Robotic Palletizing

Imporatance of Palletizing

Palletizer machines have become an essential part of automation, replacing human error and injury in manufacturing with efficiency and speed. In addition to such benefits, palletizers can handle environments that would otherwise be injurious to workers. Instead of requiring the hire of more laborers to do this work, many companies have adopted palletizers into their workplace environments in order to get the job done more quickly, effectively and safely.

What We Do

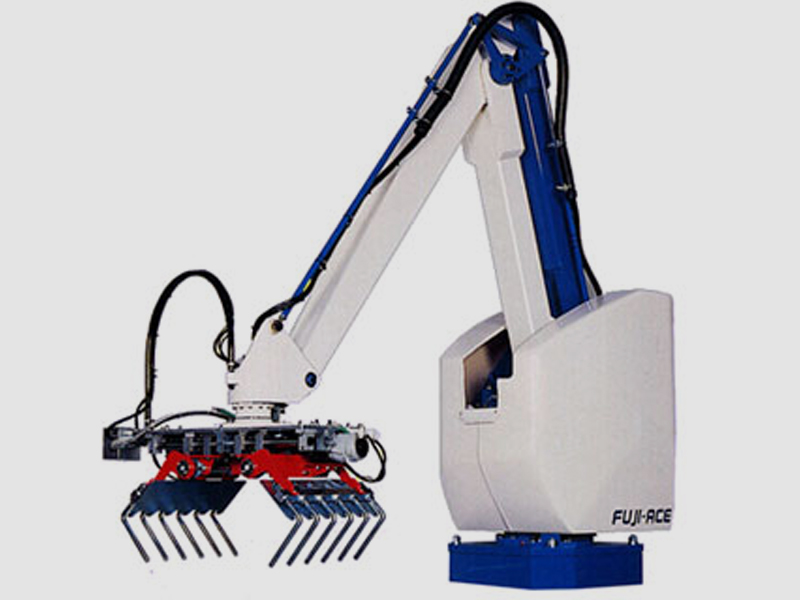

Alligator offers two types of automated palletizing. The first type, robotic palletizing, is becoming more popular and more affordable. Likewise traditional, or conventional, palletizers are also widely used including: bag palletizers, case palletizers, and gantry crane palletizers.Our engineers are experts in automating palletizing operations through both robotic and conventional palletizer system. In regards to robotic expertise, we're an official partner with Fuji and we are skilled with ABB and Fanuc as well. We can provide turnkey solutions, enabling your project to be implemented with a single source of responsibility. This eliminates finger pointing and ensures smoother project implementation.