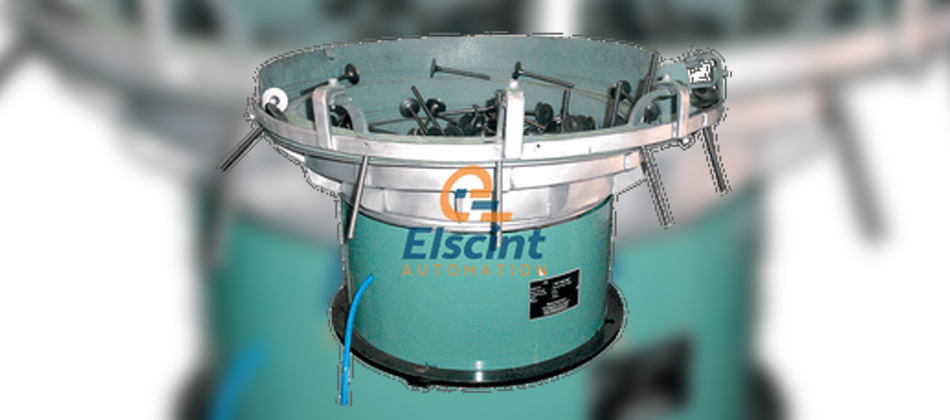

Elscint manufactures a feeding system for feeding of engine valves having dia from 20 mm to 50 mm and length between 30 mm to 200 mm. Any number of sizes between these dimensions can be fed in this system. A vibratory bowl feeder is used for feeding and orienting the engine valves. Thereafter, through a pneumatic take-up system, the engine valves are transported up to a height of 2 meters from the ground level for further feeding. Speed of between 40 to 100 pieces per minute can be achieved depending upon the sizes of the engine valves. The system results in a smooth flow of components without any starvation to the next machine. This increases the productivity of the engine valve producing units by more than 40%. The biggest advantages of this system are loading of the heavy engine valves at a height of just 500 mm, usage of the bare minimum space and flexibility of feeding various sizes of engine valves through the same feeding system. Elscint can even sell only the vibratory bowl feeder or only the pneumatic take-up unit. This feeding system is available in PLC and non-PLC (Electrical Control) versions. This system can further be modified to feed the engine valves in two outlets.

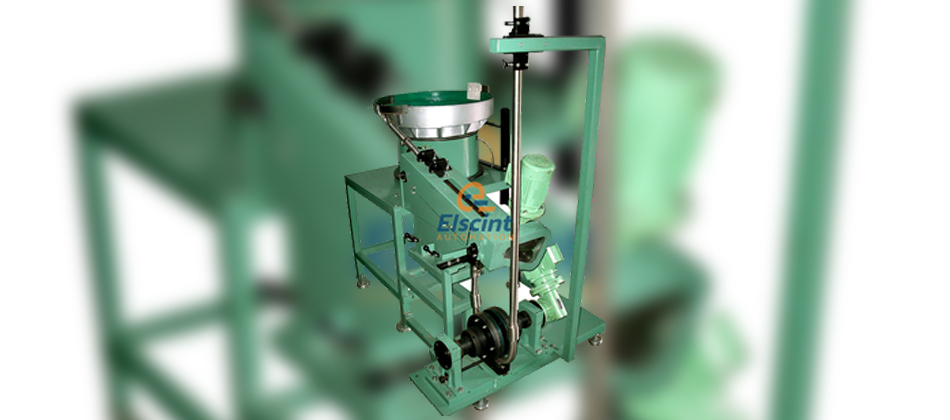

Elscint Taper Roller Feeding, Orientation and Pump Unit

The Elscint taper roller feeding, orientation and elevating pump unit is a system designed for feeding and orienting taper rollers for taper roller bearings. The system utilizes Elscint vibratory bowl feeder Model 250, Model 400 or Model 630 depending upon the roller size to feed the parts to a set of powered gauge rolls. The inclination of the rolls, plus adjustable roll spacing from one end to the other enables parts to move / travel easily and rapidly into the desired position. An important feature is that the rolls being counter-rotating will not bind or grip the parts and are extremely sensitive to fine tolerances. The rolls are driven by Elscint single reduction unit. The taper rollers are fed into the pump unit driven by a suitable Elscint reduction unit and this pump unit elevates the rollers to the desired height from where they can be fed by gravity to the work station where they are needed. The Unit thus consists of Elscint vibratory bowl feeder, two counter rotating rolls for feeding, sensors and a control panel. The unit finds applications in the bearing and allied industries.