When the requirement arises for very high speed orientation and feeding of parts, then the only alternative is to go for a Rotary or Centrifugal Feeder. These can help achieve speeds of upto 50 meters per minute. Secondly, there being no vibrations and only mechanical items, rotary feeders are more acceptable to a lot of customers who are afraid of the reliability of vibratory bowl feeders in the long run (however, using a vibratory bowl feeder from a reliable supplier like Elscint can reduce this inhibition).

Models Available

- Model 40

- Model 60

- Model 80

- Model 100

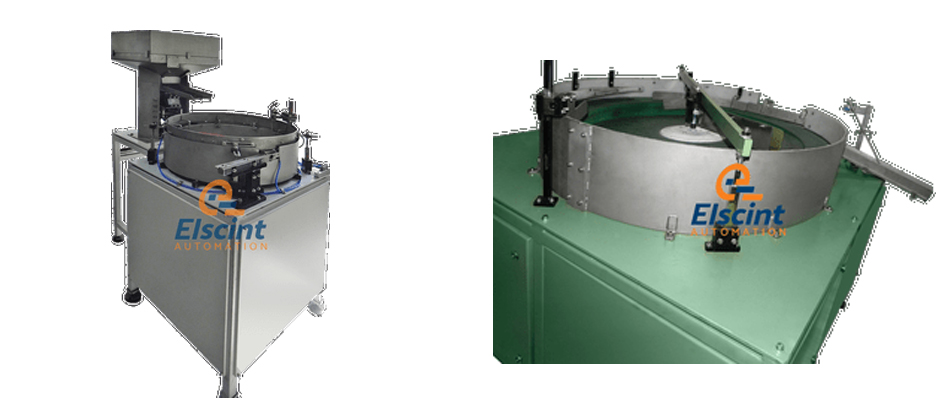

Major Features of Elscint Rotary/ Centrifugal Feeders

- Unique Double Disc drive design ensuring high speed, proper orientation & no jamming

- Separate Variable Frequency Drives, ensuring proper speed / feed rate

- Sturdy design with excellent build quality

- Optional provision for reversing of discs possible

- Pharmaceutical grade Rotary Feeders possible

- Elscinthane PU coating possible (food grade coating also available)

- Low noise level

- Clean & easy to maintain

- Variety of components can be fed in the same Rotary Feeder with simple changeover tooling

A comparison chart mentioning the advantages & disadvantages of Rotary or Centrifugal Feeders vis a vis Vibratory Bowl Feeders are given below –

| Vibratory bowl feeder | Rotary / Centrifugal Feeder | |

|---|---|---|

| Maximum speed | 12 to 15 meters / minute | 50 meters / minute |

| Usage of Air Jets | Maybe required for high speed / critical orientation | Mostly required for easy flow & orientation |

| Variety of parts which can be oriented & fed | Almost all parts | Only certain parts can be fed & oriented (eg. bottle caps, cylindrical rollers, needle rollers, flat and cylindrical drippers, bearing races, bearing rings etc) |

| Electrical supply | 1 Phase | 3 Phase |

| Variety of parts which can be oriented & fed | Almost all parts | Only certain parts can be fed & oriented (eg. bottle caps, cylindrical rollers, needle rollers, flat and cylindrical drippers, bearing races, bearing rings etc) |

| Possibility of damage to parts | Negligible | Sometimes possible for brittle parts |

| Loading quantity | High (depending upon model) | Less (Stock feeder / Hopper Elevator always required. |

| Variety of components | Possible with changeover tooling | Possible with changeover tooling |

| Food Grade Quality | Available | Available |

| Maintenance | Negligible | Negligible |

Examples of Elscint Rotary Feeders

- Round Dripper (Model RF 80)

Dripper size – (dia 16 mm x 40 mm length) -Speed achieved – 800 parts per minute

Dripper size – (dia 16 mm x 70 mm length) -Speed achieved – 500 parts per minute - Flat Dripper (Model 60)

Dripper size – (6 mm x 37 mm length)

Speed achieved – 600 parts per minute – with curved side up

Orientation – Curved side up

Dripper size – (8 mm x 41 mm length)

Speed achieved – 500 parts per minute – with curved side up

Orientation – Curved side up - Rotary Feeder for Bearing Rings (Model RF 80)

Bearing Ring sizes – dia 40 mm to dia 80 mm

Speed achieved – 300 to 500 parts per minute - Rotary Feeder for Bearing Rings (Model RF 100)

Bearing Ring sizes – dia 40 mm to dia 110 mm

Speed achieved – 200 to 400 parts per minute