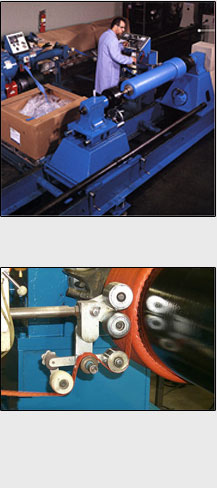

What this is Automated Roller Manufacturing?

- Advanced method for covering rollers with rubber

Who this is for:

- Paper, film and foil coaters and laminators

- Tissue and towel embossing lines

- Corrugated box and folding carton plants

- Wood and lumber processing lines

- Steel, aluminum and red-metals processing lines

- Rotogravure printers

- Offset printers

What problem this solves:

Virtually eliminates the problems most often associated with the wrapped, layered (calendered) method of roll covering using thin sheets of rubber wrapped around the roll core

- The extrusion process prevents entrapped air cells and blisters creating localized low spots

- Reduces process variability and enables consistency in repeat orders

- Enhances the rubber-to-core bond between the rubber covering and the roller core, because the rubber is applied under pressure to the bare core

- Filters out most foreign particles or contaminants in the rubber during the extrusion process

- Allows tougher rubber compounds to be applied to the roller that would otherwise not be suitable using the calendered method

Why this is special:

Creates a homogenous, monolithic roll covering after the rubber is vulcanized

Availability, and when it can be delivered:

Standard product; Imperial Rubber has two automated roll builders which provide scheduling flexibility to meet your needs

Capable of covering rolls to 60 inch diameter and 300 inches in length

Emergency services available

Comparison to competitive products:

The conventional calendered method of roll covering frequently entraps air in the layers causing localized low spots that may appear only when the roll is placed in service. The extrusion system virtually prevents this from occurring by virtue of it’s method of application.

Rubber applied to the roll core using the calendering process cannot be filtered thus leaving contaminant particles in the roll. These may be fall out during roll use leaving pin holes in the roll surface.

Calendered roll covers frequently have significant seam lines that cause problems in coating and laminating processes. These seams are also a point of weakness in the covering if the roll is under a substantial operating load.

Calendered rolls inherently have significant roll-to-roll variability due to the wide variations in manufacturing methods used to apply the rubber. The automated extrusion process provides for a repeatable manufacturing method documented on work order routers providing roll-to-roll and order-to-order consistency.

The calendering process applies the rubber to the roll core at room temperature. However, rubber does not want to adhere to a surface when cool. The automated extrusion process heats the rubber to a process temperature that creates a tacky surface when forced against the roll under pressure by the extrusion applicator head. This promotes a stronger bond between the rubber and the core.

Features:

- Monolithic roll covering without layers or seams

- Improved bonding of rubber to roll core

- Contaminant free working surface of roller

- Tougher rubber formulations can be used

Typical Applications:

- Coater applicator rolls

- Laminating and nip rolls

- Ink and water form rollers

- Flexo metering and wiper rolls

- Gravure impression rolls

- Glue and adhesive spreader rolls

- Bridle & turn rolls

- Squeegee and wringer rolls

- Pinch & table rolls

- Feed & pull rolls

- Impression rolls

- Embossing rolls

- Wire and felt rolls