Vacuum Static Cast Polyurethane System

One of the many things that set Imperial apart from the crowd is our ability to develop new products that meet customers’ most demanding quality specifications. An example is our ability to deliver high performance vacuum-static cast polyurethanes

What are Polyurethane Rollers?

- Rollers made of cast polyurethane

Who this is for:

- Paper, film and foil coaters and laminators

- Tissue and towel embossing lines

- Corrugated box and folding carton plants

- Wood and lumber processing lines

- Steel, aluminum and red-metals processing lines

- Rotogravure printers

- Offset printers

What problem this solves:

- Dramatic increase in roll life compared with conventional urethanes and rubber

- Can deliver a more precise film in certain coating applications

- Exceptional cut resistance in harder durometers

- Better vibration dampening than rubber

- Abrasion resistance that exceeds almost all rubber compounds

- Folder split nips that outperform other products with our “gapless” technology

Why this is special:

- Fewer roll changes reducing downtime

- Better coating laydown across the web, strip or sheet

- Sharp edges of metal or wood cause less wear or roll damage

- Roll shape is maintained longer, reducing frequency of roll changes

- Commercial printers using split nips receive an immediate performance increase

Availability, and when it can be delivered:

- Standard product; a wide inventory of molds provides flexibility to meet your scheduling needs

- Emergency services available

Comparison to competitive products:

- Imperial Rubber designs its own urethane formulas to suit your application

- The purity of these rolls is unsurpassed by other

polyurethane rolls we have measured from any other source - Unmatched batch-to-batch consistency means you receive the most consistent results from every roll you use

- Our mixing technology and reaction kettles, coupled with state-of-the-art filtering methods provide you with rolls free from contaminants

Features:

- Ultra pure cast polyurethane polymers

- Virtually contaminant free throughout roll

- Hardness from 15 Shore A to 65 Shore D

- Uniform hardness across the roll face

- Film-grade materials

- Exceptional consistency from roll to roll

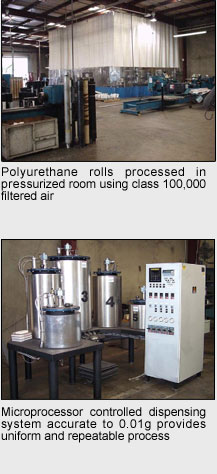

- Rolls processed in pressurized room using class 100,000 filtered air

- Microprocessor controlled dispensing system accurate to 0.01g provides uniform and repeatable process

- You can specify virtually any color at no additional charge

Typical Applications:

- Coater applicator rolls

- Gravure impression rolls

- Bridle rolls

- Pinch & table rolls

- Feed & pull rolls

- Impression rolls

- Embossing rolls

- Split nips and scores

Download