New Advanced Material for Steel and Aluminum Lines

The Problem with Current Tension Rolls

The tension rolls in leveling and slitting lines are often a source of problems that cause reduced productivity and contribute to quality issues with the sheet, strip or coil. The type of material used in the roller covering, and the accuracy of the rollers with respect to each other, play an enormous roll in the output of the process. Many slitting, leveling and cut-to-length process lines use either rubber covered or nonwoven (compressed fiber) mill rolls to control tension.

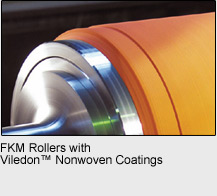

The FKM Solution – Longer Life, No Slipping

FKM nonwoven mill rolls provide up to 50 times the life of rubber rollers in these positions while providing superior tension control... which means no slipping. Their unique structure provides up to 5-times the torque transmitted in a wet or oily strip while retaining unmatched cut resistance. FKM has developed a proprietary material for these applications, and Imperial Rubber Products is the western service and technical center for FKM nonwoven mill rolls

If you are currently using nonwoven mill rolls from 3M or Toho, we can replace the material with the FKM compressed fiber technology without the need to modify the rollers (in most instances). The FKM technology provides superior consistency of hardness across the roll face. It also provides, in most cases, a longer initial coefficient of friction due to the superior binder used in the making of the nonwoven fabric

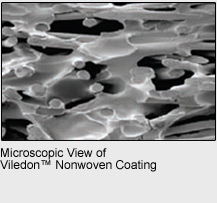

Background on Nonwoven Rolls

Any nonwoven material is composed of fibers, that are bonded together to form a randomly oriented fabric. In the case of nonwoven rolls, enhanced mechanical strength is required. Therefore, the fiber structure is impregnated with an elastomeric binder material. The number of possible combinations of fibers and binding systems is almost unlimited, so that nonwovens of very different hardness, elasticity, and porosity can be designed. At the same time it is possible to optimize the resistance to various chemical media.

Applications in the Steel and Aluminum Industries

- Application of an accurate, streak-free oil film

- Homogeneous squeezing of liquids such as oil, water based solutions of acid or caustic nature in rolling mills, pickling- and cleaning lines

- Driving and braking of strips or sheets in slitting or cut-to-length lines

Applications in the Automotive Industry

- Squeezing of washing media in blank washer systems

- Removal of residual particles in the blank washing process

- Preparation of homogeneous oil films for stamping

Applications in the Textile Industry

- Squeezing of liquid media in wet-on-wet operations

- High draining degree at a minimum residual moisture

Contact us for more information, or to discuss the specific requirements of your application.