Bakery Shortening & Margarine Plants

Shortening

In modern days, fast foodhas multiplies the demand of baked food (shortenings ),

Baked food imposes the film of fat through the food in such a manner that, the protein & carbohydrade componants do not cook to hardended mass.

Sterine + vegetable oil = all purpose shortenings

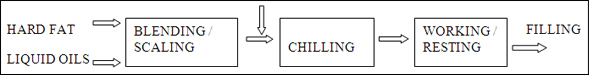

In this process quick solidification & subsequent crystallization function requires careful control. Normally it follows below path

Mixing → heating → supercooling → crystal growth → rotating shaft → plasticized filling → tempering → room sales

Generally 8-12% nitrogen or air is introduced in chilled product, to improve shortening textural appearance & colour. Stabilize it by making it more homogenuous & improve its creaming properities by contributing gas to expand dough & batter for subsequent baking operations.

Margarine

Margerine is a plastic fat food product containing 80 % edible fat, 20 % auueos phase ( specially cultured skim milk ), also salt, vitamin, food colouring and other additives

Auueous phase provides an excellent growth media for harmful bacteria. So must be carfully prepared & sterillized, for proper blending these tanks are jacketed by hot water media.

Depending on the undergone processes the final product is named like Table margarine, tube filled margarine, puff pastry margarine etc.

Bakery Shortening Margraine Plants

SPECTEC is a leading manufactures & Exporter of process equipments now present Bakery Sortening Plant for processing bakery sortening. The plant will be capable of producing upto 1,000 kgs/hour when cooling from an inlet temperature of 45 C to 23 /25 C suitable for semi-liquid filling into cans.

The Capacity is dependent upon product formulations and inlet temperature of the product to be processed.

The plant consist of the following :

- Essessprocessor-Heat transfer cylinder assembly.

- Crystal distribution cum stabilizer.

- Triplex plunger reciprocating pump.

- Nitrogen gas purging system.

- Interconnecting product pipeline.

- Control panel.

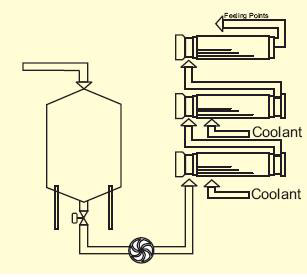

Essess Processor

Two numbers of interconnected Esessprocessor consisting of a single horizontal heat transfer cylinder assembly mounted on an open frame.The cylinder is jacketed and lagged for use with glycol solution. The removable heat transfer cylinder will be internally hard chrome plated. TheEsessprocessor shaft is concentrically mounted within the cylinder and has four diametrically opposed rows of floating type scraper blades and is driven by suitable motor hoseproof to IP55 standard via belts and pulleys suitably guarded.

All the product contact parts are made of stainless steel AISI 304 materials. The scraping blades, seal parts and 'o' rings will be copatible with the product. The frame and the external product non-contact parts are in carbon steel and finished painted with metallic paint.

Essessprocessor chilling jacket is suotably insulted for eliminating heat loss and cladded with stainless steel sheets for maintaining utmost hygiene.

Crystal Distribution Cum Stabilizer

Horizontally mounted and sequentially connected to the two number of Essess processors mentioned above.The cylinder has two rows of fixed pins at 180 with a concentric shaft carrying pins in a helical arrangement which intermesh with fixed pins while rotating, driven through a gear box and a suitable motor hose proof to IP 55.

All product contact parts are made of stainless steel AISI 304 materials. Two numbers of heaters are provided for heating of the product in case of product solidification inside the product cylinder during power failure or production stoppage.

The cylinder is suitably insulated for eliminating heat loss and cladded with stainless sheets formaintaining utmost hygiene.

Triplex Plunger Reciprocating Pump

Triplex model single acting reciprocating plunger pump is used for feeding the product to the system. The capacity of the pump is 1,690 litres/hour driven by a suitable motor hose proof to IP 55. All product contact parts are of stainless steel AISI / 316 materials and the product handling compartment is suotably jackated for hot water / steam circulation for melting the product.

Nitrogen Purging System

This consist of pressure regulating value for regulating the line pressure with two numbers gauges for reading the line pressure as well as cylinder pressure. This system has flowmeter with flow regulating value for adjusting the required amount of gas to be mixed with the products.

Interconnecting Product Pipeline

The interconnecting product pipeline is jackated for heating in case of product being solidified inside the pipeline. Further each section of the product pipeline is interconnected suitably for continuos heating of the entire length of the product pipeline.

Control Panel

This control panel not only enables smooth and trouble free handling of the product but also ensures safe operation of the plant. The unique deisgn features of the control panel prevents mishandling of the plant thereby avoiding costly damages.

The unit does not start unless temperature of the product at certain specified locations is below the specified limit.At the same time the unit does not stop even the temperature ate the specific locations goes below the specified temperature during the operation of the unit. This safety factor avoids damage to the equipments of the plant when the product inside the equipments as well as pipeline is solid in case the plant is stopped due to power failure or product change over.

The Bakery Shortening Plant enumerated above is not the only capacity limit but also we can manufacture higher production capacity plants as may be required by the clients.

We can also procure other fabricated equipments like fat blenders of various capacitiesin both Stainless Steel and Carbon Steel as per the specific requirements.