Continuous / Batch Vegetable / Cooking Oil Refinery plants

SPECTEC offers Continuous Refinery Plants, with latest technologies, both manual & PLC controlled plants

Oil Refining is the process of removing unwanted Moisture, Impurities, Free Fatty Acid, Gums, Waxes, Color & Odors.

Oil can be process by two different methods :

- Batch refinery

- Continuous refinery

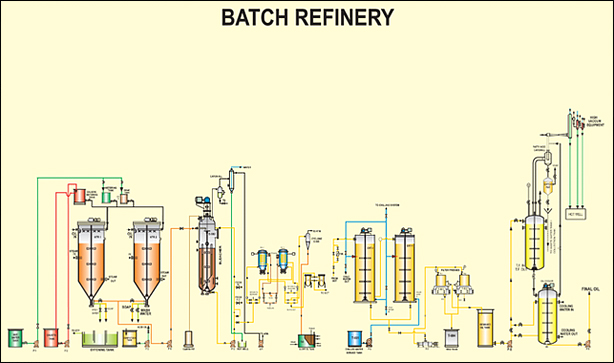

Batch Refinery

In batch refining process a measured batch of crude oil is processed in sequence of Nutralizing , Bleaching, Dewaxing & Deodorizing.

Crude oil from obtained from expellers, solvent extraction plant contains foreign impurities such as mucilage, gums and unfiltered proteinous matter from the seed. It also contains gums which making it unfit for edible purpose. Batch refining consists of following sections - Neutralizing, Bleaching, Dewaxing, Deodorizing.

The first stage of refining is to separate these gums & foreign impurities with chemicals and hot water treatment called as degumming process. Thereafter the degummed oil is further processed in bleaching section under vacuum and treated with bleaching earth and carbon for reduction of colour pigments. Next it will be deodorized under high vacuum.

The edible oil obtained from batch refinery is of good quality meeting all requirements of international standards.

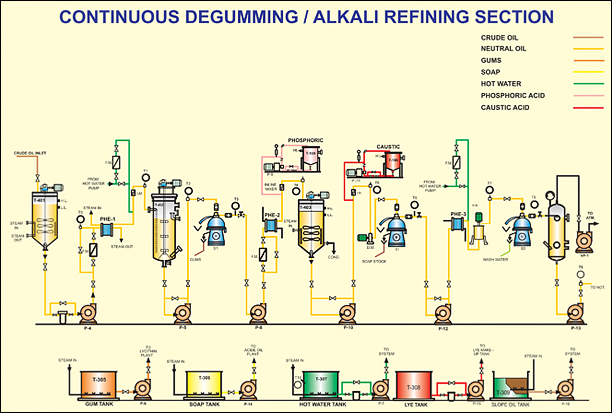

Continuous Refinery

Basic process of refining is same in both batch & continuous refinery. Only difference is instead of a measured batch, crude oil is processed continuously with constant stream of flow. Inbetween required utilities & chemicals are added continuously in measured quantity. Basic stages of the process are as : Nutralizing , Bleaching, Dewaxing & Deodorizing.

Crude oil from obtained from expellers, solvent extraction plant contains foreign impurities such as mucilage, gums and unfiltered proteinous matter from the seed. It also contains gums which making it unfit for edible purpose. Batch refining consists of following sections. Neutralizing, Bleaching, Dewaxing, Deodorizing.

Therefore the first stage of refining is to separate these gums & foreign impurities with chemicals and hot water treatment called as degumming/Nutralizing process. Thereafter the degummed oil is further processed in bleaching section under vacuum and treated with bleaching earth and carbon for reduction of colour pigments. Next it will be deodorized under high vacuum.

The edible oil obtained from refinery is of good quality meeting all requirements of international standards.

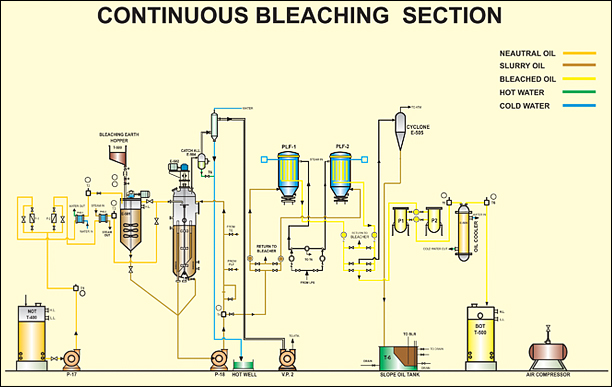

Bleaching Section

De-gummed oil form NOT is pumped to the BLEACHER at the same time part of oil is carried to the SLURRY TANK oil is cooled before passing to slurry mixer. Pre-calculated amount of bleaching earth is added in the slurry mixer, this slurry is sucked by means of vacuum to the bleacher. After proper holding & mixing this oil is sent to the alternative operating set of PRESSURE LEAF FILTER after this filtration oil is again filter by alternative operating set of polishing filters. Then it is cooled by shell and tube cooler before it reaches to the BOT.

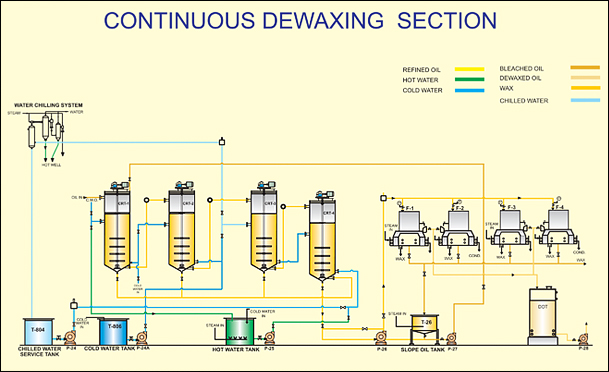

Dewaxing Section

De-waxing is the process to cool the oil at the temperature, at which wax converts in solid form ( actually in slurry form ) but oil remains in liquid form as it is. For this oil is cooled slowly and step by step, with cold water and then chilled water. The bleached oil from BOT is pumped continuously with stream of flow to the series of crystallizers, where oil is cooled slowly and steadily in counter current manner, so as to crystallized the wax for the purpose of easy filtration. After this oil is carried to the maturator. Which is again in series to the crystallizers, here oil will maturated in terms of temperature it will be increased or decreased as per requirement to assure the crystal formation of wax. Finally this oil is filtered by the filter presses.

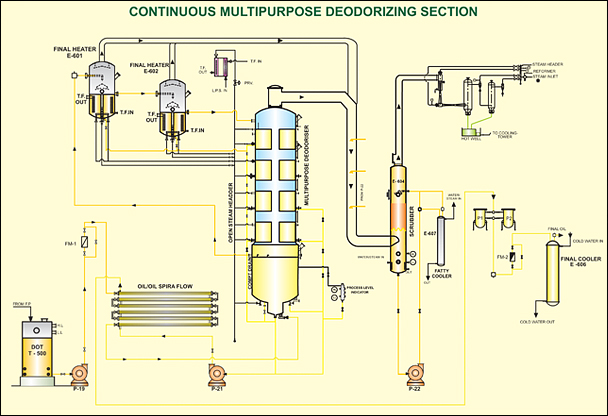

Deodorizing Section

Deodorizing is nothing but The DISTILLATION process. in which fatty acid is distilled from oil. Under high temperature condition and in presence of high vacuum, with the help of sparging & agitation steam. Further this fatty acid in vapors form, is condensed & recovered in liquid form by the vapors scrubbing system. De-waxed / Bleached oil from intermediate storage tank is pumped by to primary heating plate heat exchanger. which is used only in startup conditions. To heat the incoming cold de-waxed oil. Further it will be travel from oil to oil heat exchanger. Where de-waxed oil is getting heated by the outgoing hot refined oil. Then this oil is going to The PRE-HEATOR Via. Peripheral coils of the regenerative heat exchanger which is the bottom compartment of the multipurpose deodorizer. In regenerative heat exchanger de-waxed oil flows through the coils & refined oil flows through the open space of the exchanger. In counter current manner, continuous steam agitation at open steam side assures continuous and maximum heat exchange. After recovering maximum heat from the refined oil. Oil is further heated up to the required temperature , suitable for the deodorizing in final heater. this heater is equipped with agitation and sparging steam, continuous flow of superheated steam through this assures effective primary vaporization of fatty acid.

Further this overflows to the multi-compartment DEODORIZER. Deodorizer is multi-compartment vertical vessel, where each and every trays are specially designed which Ensures uniform distillation of odoriferous substances.Oil is overflows from tray to tray. Specially designed trays provide sufficient mass transfer surface for effective removalof volatile matters. Flow control system at the outlet of the deodorizer, ensures the maintenance of required level at the bottom tray. The steam used for stripping off volatile matters in the oil is distributed evenly and intensively the steam meets the deodorized oil. Stripped off the volatile matter and rises through the vacuum. Stripping the volatile matter from the oil. The counter-current flow of steam and oil like this in specially designed trays lower steam consumption, than the conventional deodorizers. The deodorized oil leaving regenerative heat exchanger and finally cooled by water in heat exchanger finally this oil is passed through the alternatively operating set of polishing filters.

Vapour Scrubbing

The volatile matters consisting of free fatty acid and other odoriferous substances stripped from the deodorizer are led to the vapor scrubber located at the outside of the deodorizing column. In the scrubber volatile material rises through the bed of pall rings and meets liquid fatty acid sprayed from the top. vapors are condensed, cooled, and then recalculated to condensed fresh vapors. Excess distillate collected is led to the storage tank, whenever high level reached in storage space below the scrubber. Fatty acid scrubber is specially designed for minimum carryover of fatty materials, to the vacuum system.