Dry Fractionation Plant, Dewaxing Plant & Winterzation Plants

SPECTEC offers a wide range of batch & continuous Dry Fraction Plants.

Most of the natural oils & fats have only a limited applications in there original forms as a consequence of there specific chemical composition. In order to widen there uses the oils goes through variety of modifications, Fractionation is one of them.

Fractionation is the fully reversible modification process. It is basically a tharmochemical separation process in which a multicomponant mixture is physically separated in to two or more fractions with distinct physical & chemical properties. The can be based on a difference in solidification, solubility, or volatility of different compounds.

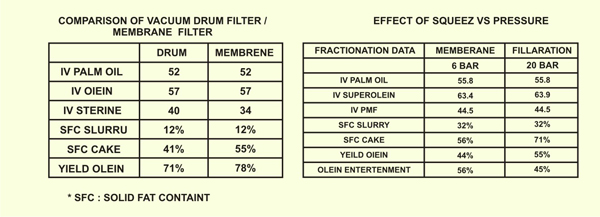

SPECTEC”s Dry Fractionation plant is a custom design to allow you to achieve selective crystallization of different triglycerides in edible oil. This is plant you can count on producing stable & filterable crystals giving you a product to fit your standards and quality requirements.

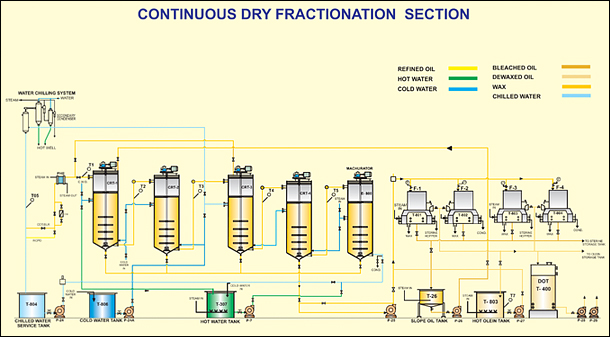

SPECTEC’s system is designed to process crude, pre-treated or RBD palm oil. The process is divided in few steps as - Feed oil heating, Crystal formation under controlled cooling, Crystal growth, Crystal maturation, Filtration.

Palm Oil

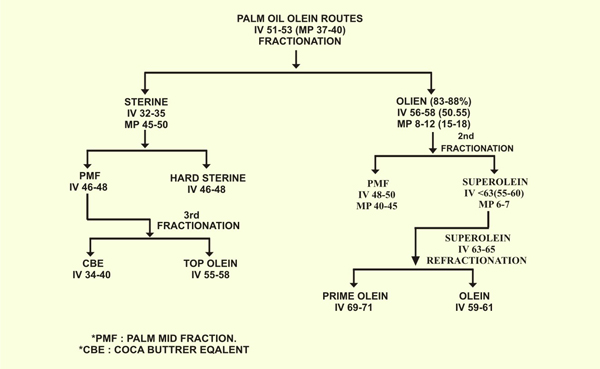

The latest development in fractionation of palm oil have made it possible to produce super olien with IV of 70 & more these prime or top olien products are obtained by re-fractionation of super olien.

General uses of Olien - cooking, salad, bleaching

General uses of Sterine - frying fats, margarine & shortlenings.

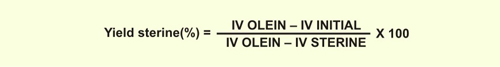

IV is a measurable degree of instauration. during crystallization more saturated & hence higher melting trigecerides concentrate in to solid phase, where as the olein fractions becomes enriched in more unsaturated triglycerides. The change in IV also measurable for separation efficiency as it can be used to quantity the separation.

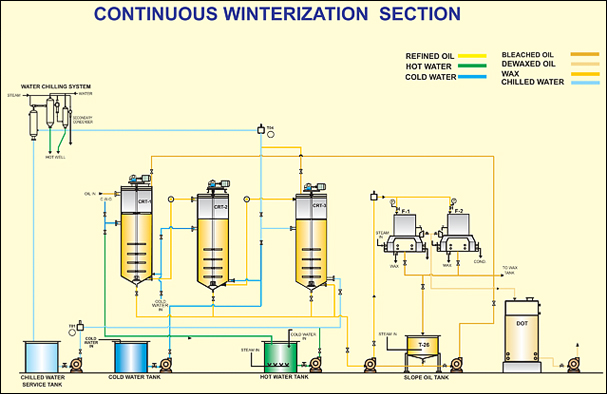

Winterization Plants

Winterization is anarrow process, it same as that of dewaxing. This process is applied to remove small quantities of solids from oil that would normally cause cloudiness of the oil when kept at refrigeration temp. these substances can be saturated glycerides or waxes. Waxes are esters fo fatty alcohole and fatty acid, which have a very low solubility in oil. There quantity is different in different oils. Generally varies in between 48-2000 ppm. In order to obtain an oil with good cold stability, the wax contain needs to reduced to the level of about 10 ppm. In this process cooling rate & agitation are carefully controlled to promote the formation of nuclei that will serve as the sites for crystal growth.