Hydrogenation & Vanaspati Plants

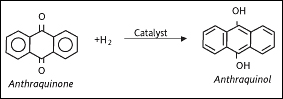

Hydrogenation is the chemical addition of hydrogen to a hydrocarbon in the presence of a catalyst, a severe form of hydrogen treating. hydrogen is added to a molecule that is unsaturated with respect to hydrogen. In either case, the resulting molecules are highly stable.

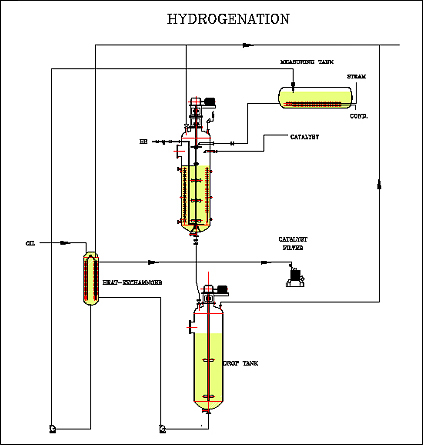

Hydrogenator Design and Control

The use of hydrogen requires precautions against creating an explosive mix of hydrogen and air. Typically, a hydrogenation vessel undergoes a pressure test followed by several nitrogen purges before hydrogen is introduced. Similarly, at the end of the reaction process, the vessel is purged with nitrogen in order to leave it in a safe condition. Normally, a hardwired safety system confirms the pressure test and nitrogen purge phases before allowing the hydrogen line to be opened.

Hydrogenation requires high pressures to be maintained in the reaction vessel - giving problems over maintaining seals around agitators which in some cases require additional seal integrity checks or upgrades to incorporate magnetic coupling systems.

Hydrogenation also tends to be a highly exothermic reaction, resulting in demanding temperature control requirements.

A control system must therefore provide flexibility in the way in which accurate and repeatable control of the hydrogenation environment is achieved and will include the following features:

- Sequential control for vessel pressure testing, purging and hydrogen addition.

- Precise loop control for temperature and pressure

- Secure collection of on-line data from the hydrogenation process for analysis and evidence.

- Local operator display with clear graphics and controlled access to parameters

Vanaspati Plants

Spectec offers a wide range of vanaspati manufacturing plants

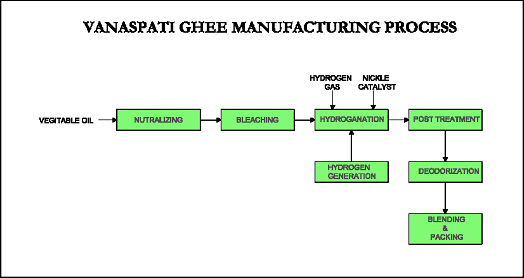

Vanaspati process was developed & introduced as an best cheaper option for ghee. Which involves fully or partial hydrogenation process. In this process raw material goes through the various process, following fig. shows the typical flow dig. Of the same

Vanaspati is the right replacement for those sections of society who cant afford hard fat diet in terms of nutrition also it protects them against oxidative rancidity of oil.