Effluent Water Treatment Plants

SPECTEC offers a wide range of new generation Effluent Water Treatment Plants which are having various industrial applications. Process Description & Unit operations.

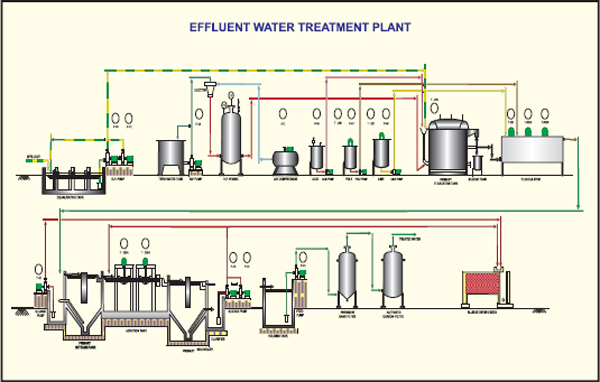

The proposed effluent scheme is based on Dissolved Air Floatation Technique followed by the conventional activated sludge process and pressure sand filtration and activated carbon filtration to achieve the final parameters.

Unit operations - Equalization, Acidification, Primary Floatation, Fat Recovery, Chemical Conditioning, Flocculation, Removal of Chemical Sludge, Biological Oxidation by Activated Sludge Process, Bio-clarification / sludge recycle, Up flow pressure sand filtration, Activated carbon filtration, Reuse options.

| Parameters after final treatment. | |

| Ph7 | - 8 |

| Cod | < 2 0 0 P P M |

| Bod | < 3 0 P P M |

| Tss | < 5 0 P P M |

| Fog | <5 PPM |

| Temp | ambient |

| Colo | rsparkling white |

| Bio assay90 % survival in 96 hours on fish. | |

The segregated effluent streams from the process plant will join the equalization tank, with adequate retention time. The effluents will be received in the equalization tank to check and stabilize the variations in the PH and other impurities. By this step differences in the temp. rate of flow of various streams balances out and acquire homogeneity so as to facilitate optimum treatment conditions. The homogeneous effluent from the equalization tank will be pumped at the required rate into the primary floatation tank and predetermined quantity of acid will be dosed to spilt the free floating as well as the emulsified oils and fats and other colloidal impurities. At this PH (3-4) most of the soluble and insoluble fats and oils are separated and could be separated quickly by injecting the dispersion water made by the dissolved air floatation technique. Air is dissolved in water under pressure and is injected in the floatation tank, wherein because of the difference in pressure, air comes out in water as of millions of minute air bubbles. This minute air bubbles get attached to the suspended and colloidal impurities and float them to the surface of the floatation tank. These floated oils and greases could be removed with the help of mechanical scraper provided and could be used for making acid oil. Or crude soap hence a valuable by-product.

After the removal of fats and oils acidified effluent will be coagulated and neutralized with help of common coagulants like hydrated lime solution in specially designed flash mixer cum flocculator. In order to affect complete coagulation it advisable to make use of polyelectrolyte which will combine the flocks as well as the rate of separation of chemical flocks to achieve the max. clarity. The purpose of chemical coagulation is to destabilize the floating, emulsified and suspended contaminants, such that the particle contacts and agglomerate, forming flocks that separate out of the solution. de-stabilization is accompanied by the addition of chemical coagulants like lime and alum. Highly charged hydrolyzed metal ions produced by the chemicals in the solution reduce the repulsive forces between the contaminant particles. With the force of repulsion suppressed, mixing gently results in particles contact and forces of attraction causes the particles to stick to each other, producing progressive agglomeration coagulant, used to enhance the process of flocculation.

The coagulated effluents from the flocculator will be piped down in the primary settling tank. The chemical sludge settles at the bottom of the tank by gravity. The chemical sludge produced is removed periodically and is de-watered with the help sludge drying beds and treated water is taken further treatment.Also provision shall be made to recycle the effluent into the equalization tank and reprocessed till it produces the required characteristics before disposal. About 70 - 80% reduction in BOD, COD, suspended solids and fats and oils are envisaged by these steps. Since primary treatment alone is not sufficient to meet the required standards a secondary system is incorporated. Since the biological load is high single stage activated sludge process is incorporated. The primary treated water is treated further by the activated sludge process to bring down the parameters with in the prescribed limits.

The primary treated effluent is aerated in the aeration tank by surface aerators by providing enough micro organisms and nutrients. The general biological reaction that takes place is a predator prey reaction. The waste water supplies the organic matter (biological food) and aeration furnishes the dissolved oxygen. The primary reaction is the metabolism of the organic matter and uptake of the dissolved oxygen by bacteria releasing the C02 and producing substantial increase in the bacterial population. The secondary reaction results from the oxygen used by the protozoa consuming bacteria releasing carbon dioxide and protozoal cells. About 85-90 % reduction is envisaged by this process.

The effluents after the aeration enters in the secondary settling tank and the biological sludge is allowed to settle down. The sludge is drawn off and re circulated back to the aeration tank to maintain the biological population in the aeration tank whereas excess sludge is wasted through the sludge drying beds. Treated water flows in to a holding tank and is filtered in an up flow pressure sand filter to trap further suspended solids and other impurities and the filtrated water is passed through an activated carbon filter to absorb the traces of the organic impurities to prevent the smell and colors. The final treated water shall be sparkling white in color with no smell and could be taken back for indirect cooling and general washing, agricultural and gardening process.