+91 895 6627 790 info@unikraft.in

Induction Heating System

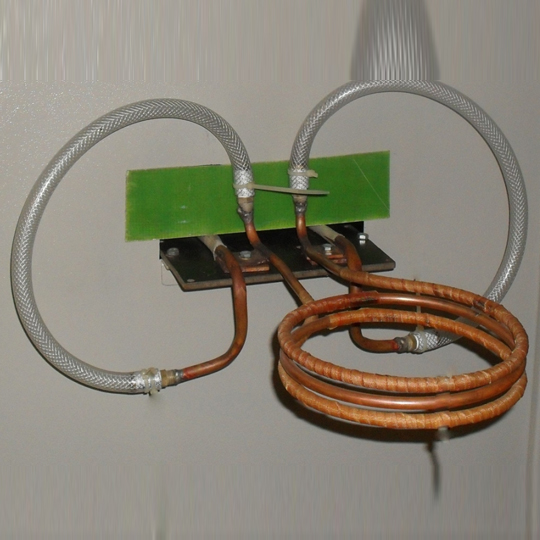

We design & manufacture Induction Heating Systems which are used for hardening, annealing, stress relieving, pre & post heating of job during welding as well as many other application as pre customer requirement.The working principle of inductive heating system is based on an alternating current flowing through a single or multiple turn coil also called as inductor.This inductor crates an alternating magnetic filed at high frequency in its proximity.So when any magnetic material or electrically conductive material is present in this highly alternatic magnetic filed heat is generated in that material. The amount of heat generated depends upon the power of the induction unit, the frequency,the gap, the material etc.

Technical Specification :

| PARAMETER | TECHNICAL SPECIFICATION |

| Model/Rating | 10 KW to 200 KW & more powerful machines on customer request |

| Input Mains | 3 Phase, 440 VAC ± 10% |

| Frequency | 47 to 53 Hz |

| Inrush Current |

115% of full load rated input power

|

| Inductor Frequency |

PWM 50 Hz to 200 Khz |

| Waveform |

Pure Sine Wave |

| Power Factor |

0.8 lag to Unity |

| Overload |

110% for 20 min or 140% for 5 sec. |

| Overheating Protection |

Cooling water recirculating system |

| Temp. Ambient |

0 to 55° |

| Humidity |

Up to 95% RH |

| Cabinet |

Pedestal / Castor Wheel |

| Protections & Panel Indicators |

Over Current / Over Temp. / Water Fail safe indicator / Single Phase / Phase Shift |

Salient Features Of Our System :

- Fast, Flame less, Economical & suited for automation.

- Reduce Formation of Oxides.

- Energy Transfer occurs without contact.

- Designed for long life Performance.

- Water cooling recirculating system for coils & inverter.