+91 895 6627 790 info@unikraft.in

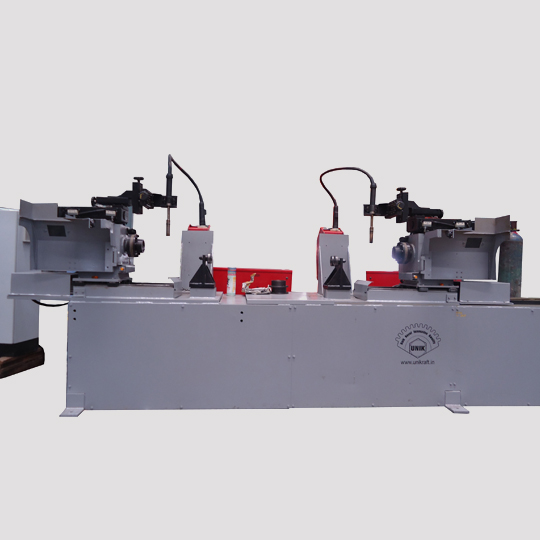

Special Purpose Machine

In today's scenario of Mass fabrication & faster deliveries, the main constraint is the availability of skilled welders. Apart from the scarcity of welders, even if we get good welders, their productivity is not consistent. The productivity is the maximum at the beginning of the shift & gradually deteriorates by the end of the shift. Due to the dependency on skilled welders, if they go on vacation or on leave, the work is hampered. Due to the above reasons, more & more fabrication companies have invested in Welding Automation.

The advantages are many. A few are named here below: :

- Consistent quality of the welds.

- Consistent productivity in output.

- Welding skills are not required.

- Any semi-skilled person can weld.

- Jobs that are difficult to weld manually can be welded.

UNIK Team has excellent experience of providing Welding Automation Solutions(UWAS) to many leading industries, ranging from welding positioning equipment to complete Welding Automation Solutions including material handling like Loading, Unloading, pre-heating, Post heating etc. Welding systems can be equipped with interchangeable fixtures so that one Welding automation system can do a variety of different parts. The welding process may be MIG / MAG , TIG, or SAW.

Features Of Our Systems :

- PLC controlled systems with HMI.

- Automatic Loading & Unloading of components.

- Pre/Post heating of components by Induction heating.

We can supply SPM's for applications such as :

- Welding Setup for Automobile components.

- Axle welding System -for Round & Square Axle.

- Circumferential Welding of Idler Rollers of Conveyor with Auto Loading & Unloading.

- Valve Face & Bore Cladding System.

- Clevis Welding Setup for Hydraulic cylinders.

- Pipe to Flange & Pipe to Bush welding system.

- Cryogenic vessel production line.

- Beam -I/H/Plus Production line.

- L-Seam Welding System.

- Cir-Seam Welding System.

- Box Girder Production line.

- Circumferential Welding Setup for LPG Cylinders with Auto Loading & Unloading.

- Rebuilding setup for Rollers or any other similar cylindrical component.

- Stator stack welding setup with Auto Sequence.

- Wind mill Tower manufacturing setup.

- Hard facing setup for plates / shells.

- Head Stock / Tail Stock Type Positioner for positioning of Long & odd shaped Jobs like chasis of dumper trucks.