+91 895 6627 790 info@unikraft.in

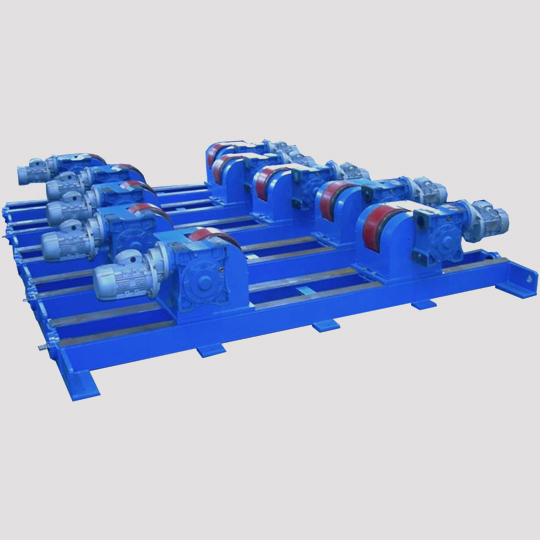

Welding Rotator

Welding Rotators are very essential equipments for heavy and light fabrication shop. They are mainly used to rotate or position the cylindrical jobs for circumferential welding (TIG / MIG / Sub Arc) or for intricate assemblies. We manufacture rotators from 1ton capacity upto1000 Tons capacity as per customer requirement with following features:-

Features :

- Steel rollers or polyurethane lined rollers.

- Our standard Rotators consists of Drive Unit and Idler Unit.

- The frame and roller brackets are fabricated from heavy sections & precision machined.

- Variable surface speed from 300 to 1500mm/m or as per customer requirement using AC Variable Frequency Drives.

- For precision movement encoder feedbacks are provided on case to case basis.

Advantages :-

- An indispensable tool for shell fabrication shops.

- Attains exceptional Quality circumferential joints on shells.

- Increased production with reduced labour skill.

- Leads to minimum handling the shell / Job.

- Lesser usage of crane reduces idle time.

- Improves plant efficiency.

Application :-

- Welding of Pipes, API pipes, Boilers, Heat exchangers, Pressure Vessels, Mounted vessels, LPG Bullets, Barrels, Tanks etc.