Hydrogenation Systems

What Is Hydrogenation

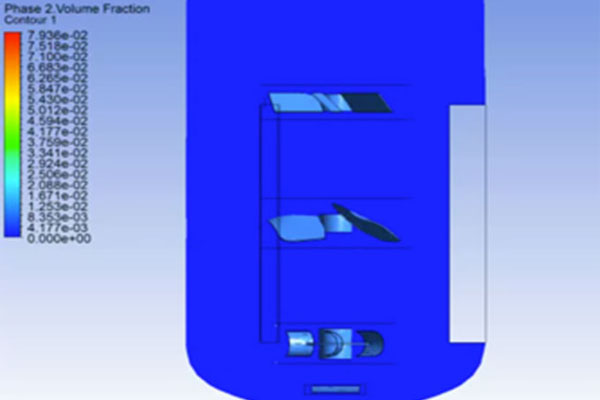

Hydrogenation is one of the most critical and sensitive processes in chemical process industries for manufacturing fine chemicals and pharmaceuticals. Hydrogen gas is released, at a certain temperature and pressure, into a hydrogenator containing the process solution in the presence of a catalyst such as Nickel.

The hydrogen is equally dispersed through the solution ensuring homogeneity. The process is successful only when the entire hydrogen gas has been uniformly mixed across the solution. However, most of the times a substantial amount of gas remains unreacted. In order to achieve complete absorption, the process needs to be repeated several times, leading to delays and increased energy consumption.

ACME™ HYDROGENATION SYSTEM

We at ACME™ provide a customized solution for your hydrogenation process needs. It is extremely important to not only understand the chemicals involved in such processes, but also a practical understanding of the process itself. As a leading manufacturer of a wide range of agitation systems, we understand the importance of role that agitator plays.

With a holistic view, we take every element of the process into consideration

- Maximum gas dispersion

- Maximum mass transfer

- Gas Remixing

- Catalyst suspension

- Heat Transfer

- Blending

BENEFITS

- Improves mass transfer

- Complete consumption of Hydrogen gas

- Improves Productivity exponentially

- Substantially Saves Energy

- Significantly reduces the process time

Since more than a decade, ACME™ Engineers have been guiding their clients I selecting the correct impeller system and accurate design of power/volume. Our high profile clients have achieved tangible benefits through our process knowledge and our three-impeller hydrogenation agitator system design.

SYSTEM STRUCTURE

A typical hydrogenator includes

THE PROCESS

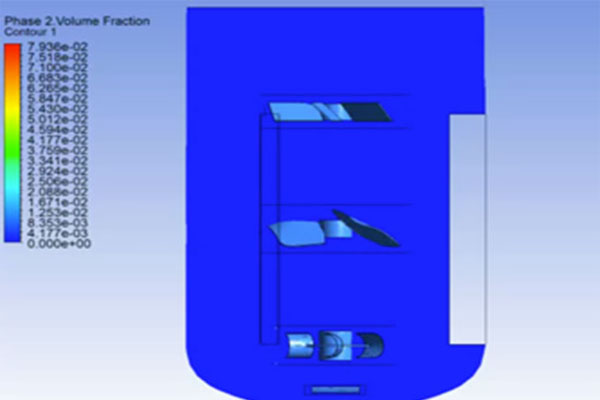

Ensuring that mixing of Hydrogen gas uniformly throughout the solution is the very critical part of the process. In such cases there are impellers at multiple levels that help uniform Dispersion, Holding & Mixing and re-enforcing of every bit of gas to be consumed.

ACME™ engineers thoroughly understand the mixing mechanics and chemical dynamics in the Hydrogenation reactor. We help you choose the right impellers for a thorough job ensuring the three factors.

DISPERSION

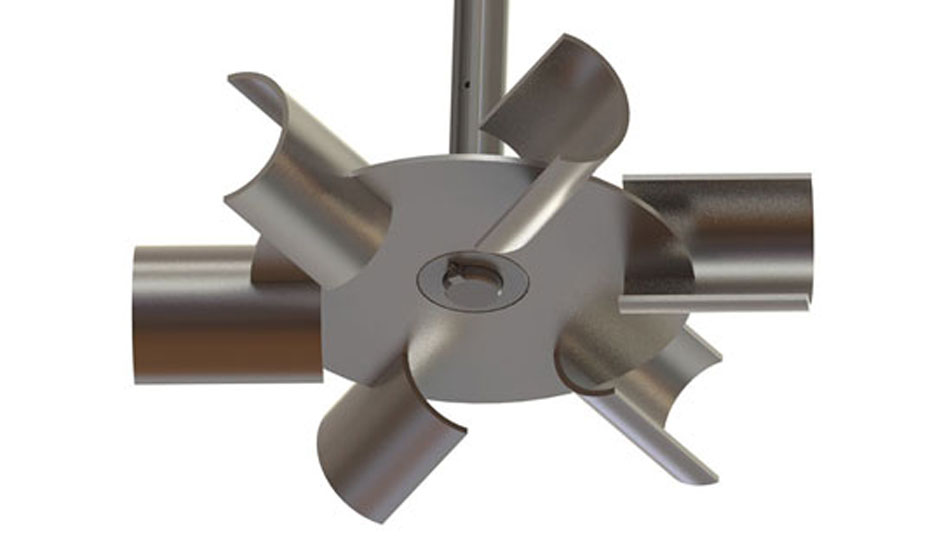

ACME™ CBT-601 IMPELLER

CBT-601 has a higher pumping capacity than a flat bladed turbine. This improves mass transfer rates which increases reaction rates. Further, the CBT-601 impeller is a reformed version of Rushton with cavities, which even at lower power (up to 60%) gives better performance as compared to the Rushton or flat-blade turbine.

Reducing the power drop off in the gassed state implies maximum availability of power for mixing. Thus, a combination of the higher pumping capacity and lower power drop off in the gassed state will ensure good suspension of the catalyst used in the hydrogenation reaction.

HOLDING & MIXING

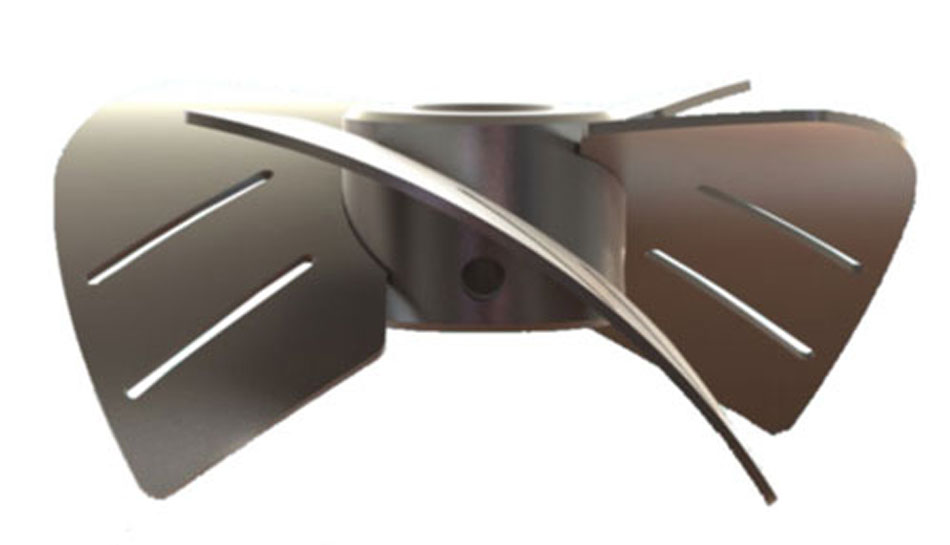

ACME™ AA-405 IMPELLER

Maximizing the reaction and thorough mixing of hydrogen gas is efficiently achieved by using AA-405 impeller. This wide-bladed hydrofoil impeller located just above the CBT-601 impeller, provides better gas holding by increasing the mixing intensity, and drawing a vortex for remixing of hydrogen gas at the surface. This ensures a 15% more mass transfer or yield with same power as that of primitive impellers.

RE-ENFORCING

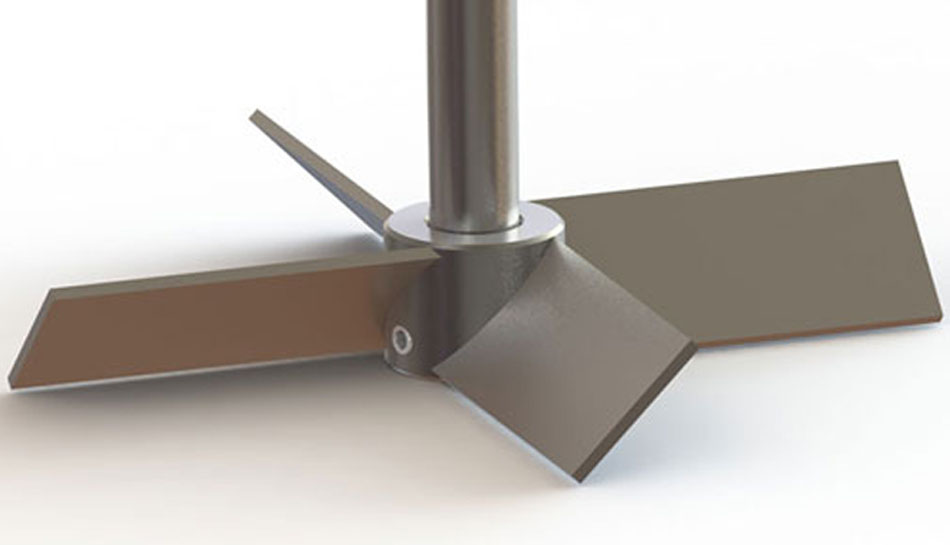

ACME™ PBT IMPELLER

The use of axial flow PBT (Pitched Blade Turbine) above the AA-405 impeller, not only reincorporates the gas, but also provides excellent mixing and eliminates gas zone formations in the upper areas (surface) of the vessel. This ensures more flow than self-inducing upper impellers and increases the heat removal rate in the hydrogenator.

Unlike self-inducing impellers ACME™'s three-impeller-hydrogenation-agitator-system does not plug or foul.

EFFICIENT CATALYST SUSPENSION

Catalyst suspension plays an important role in the hydrogenation reaction. This is efficiently achieved by the high flow rate of the CBT-601 impeller and upper AA-405 and PBT axial flow impellers. An excellent top to bottom flow ensures easy and efficient suspension and distribution of the catalyst throughout the hydrogenator.

Hydrogenation reactions is an exothermic reaction, i.e., it generates a large amount of heat, which must be removed from the process. By promoting high velocity at the heat transfer source (jackets or internal coils) the lower CBT-601 efficiently transfers the heat in the system.