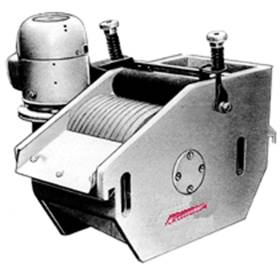

Essential cleaning unit for iron particles from re-circulating coolant in grinding machines. Capable of continuous removal of ferro-magnetic contamination. Powerful permanent magnet rotates attracting fine iron particles from coolant flow. Spring loaded rubber roller squeezes and drop back the coolant in tank. Iron sledges are removed by scraper blade, which can be adjusted. These can be easily dismantled for maintenance. Supplied complete with driving gear/motor assembly. Generally made with strontium ferrite magnets, can also be made with rare earth NdFEB magnets

Specifications:

| Cat. No. | Capacity in L pm | Driving Power (Hp) | Rotation |

| KM110 | 30 | 0.25 | 10 RPM |

| KM111 | 60 | 0.50 | 10 RPM |

| KM112 | 100 | 0.75 | 10 RPM |

| KM113 | 150 | 1.75 | 10 RPM |

| KM114 | 200 | 1.50 | 10 RPM |

| KM115 | 300 | 1.75 | 10 RPM |